1. Ensure the plane of the reflective marker and each feature of the item being scanned are at a distance of no more than 25 mm. This will better guarantee the point cloud accuracy of the 3D reconstruction of the item’s features. Note: A single scan format can be recognized as a plane with no fewer than 4 reflective markers.

2. Try to ensure that the 3D scanner can recognize the reflective markers perpendicularly from each angle as far as possible. The more accurately the scanner identifies the center of the reflective marker, the higher the splicing accuracy will be. Therefore, place the reflective markers as dispersedly as possible across all dimensions and heights of the item being scanned. If the markers are only placed on a turntable, the scanning accuracy and data quality may be affected when the item’s height exceeds 25 mm.

3. Avoid placing reflective markers on curved surfaces. When the markers bend, they will appear elliptical to the camera, leading to inaccurate center calculation and reduced identification and splicing accuracy. If placing markers on curved surfaces is necessary, try to ensure the markers do not deform and gently adhere only the center of the marker to the curved surface.

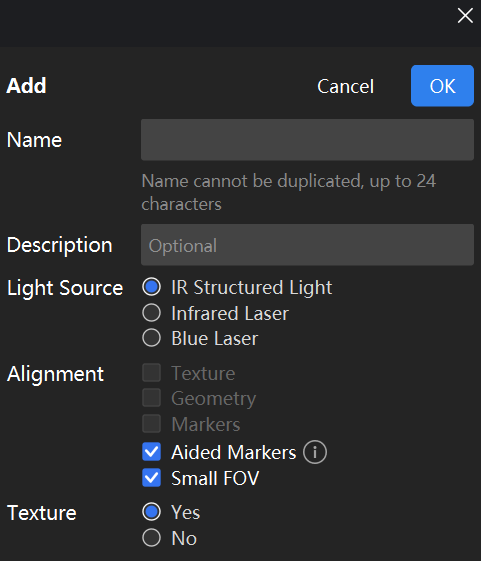

How to Use the Aided Markers Alignment Mode?

– Mode Principle: This mode uses an infrared speckle light source and combines feature points with marker points to achieve stitching, effectively improving scanning stability in environments with insufficient features.

– Stitching Requirements: The scanner must recognize at least 1 marker point in each frame to maintain normal stitching. If stitching is lost, the scanner needs to see at least 2 marker points simultaneously to relocate and restore stitching.

– Marker Placement: Avoid placing two marker points on flat, featureless areas at the same time. It is recommended to place at least one marker point on a feature with distinct curvature or corners.

– Example Application: Infant Head Scanning

This mode is particularly suitable for scanning moving subjects, such as infant heads. Using assisted marker points can effectively counteract stitching loss caused by head movements, making the scanning process smoother. It is also recommended to enable the “Small Scanning Area” mode to limit the scanning range to the head area, avoiding capturing movements below the neck and further ensuring data quality.

How to calibrate the 3DeVOK scanner with a non-matching master plate?

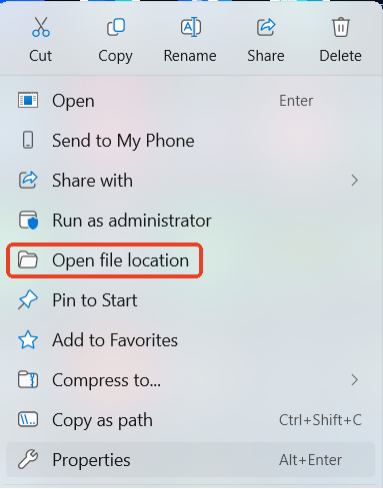

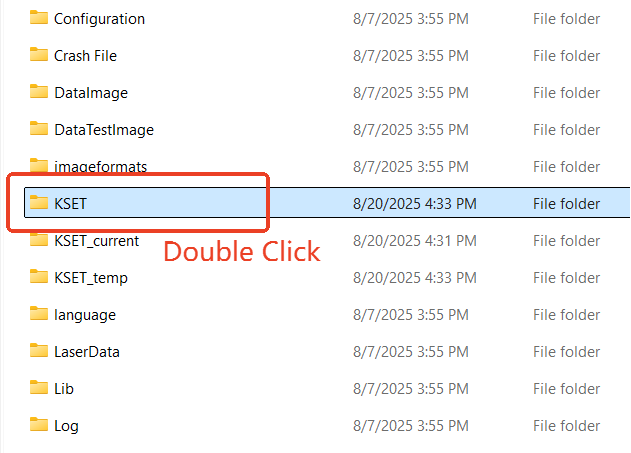

- Right-click the “3DeVOK Studio” icon and select “Open file location”.

- Find and open the “KSET” folder.

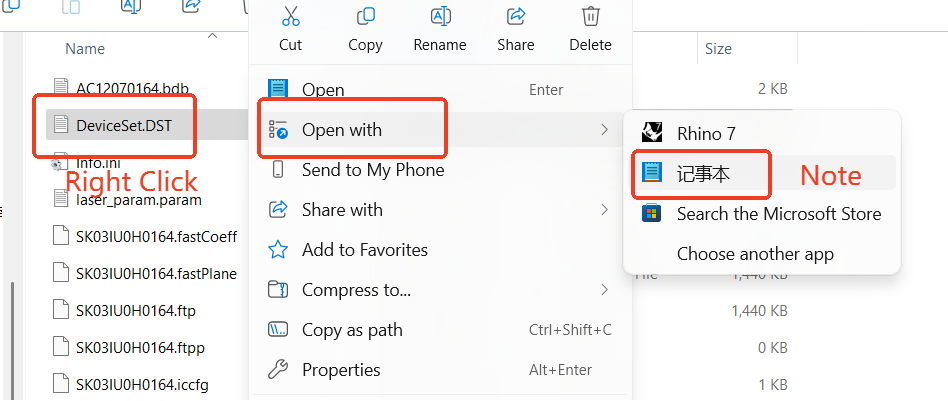

- Inside, find the file “DeviceSet.DST”. Right-click it and open with Notepad.

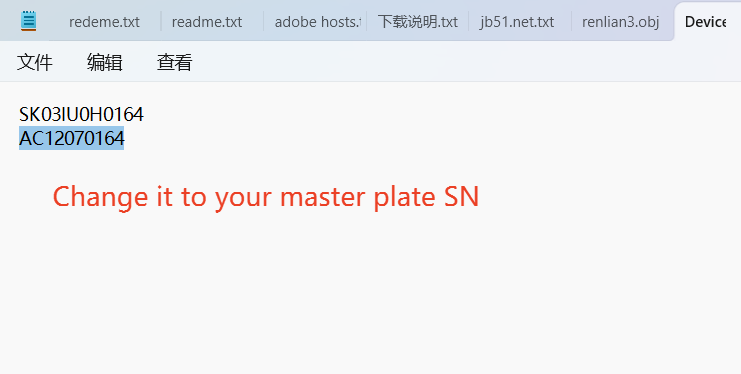

- You will see two serial numbers:the first line is for the device, the second is for the master plate. Change the second line to the new master plate’s serial number.

- Locate the storage case corresponding to the serial number of the master plateto be used, and retrieve the USB drive inside.

- Open the “KSET” folder on the USB drive.

Copy the “.bdb” file from this folder to the “KSET” folder in the software’s installation directory. (Right-click on the “3DeVOK Studio” desktop shortcut and select “Open file location” to access the installation directory directly)

Why is marker-based alignment in 3D scanners more accurate than texture-based alignment?

Marker-based alignment achieves higher precision than texture-based alignment primarily due to its stable positioning method and stronger resistance to interference.

- Marker-based alignment:

This method involves placing high-contrast fixed markers (such as reflective dots or specially coded points) on the object’s surface, providing the scanner with clear spatial references. These markers have precise and stable positions, ensuring highly accurate alignment of scanned data and minimizing cumulative errors.

- Texture-based alignment:

Texture-based alignment relies on matching visual features such as colors and patterns on the object’s surface. While it can capture rich detail, its performance degrades on smooth surfaces, uniformly colored areas, or repetitive textures. Additionally, environmental factors like lighting and reflections can affect texture stability, further reducing alignment accuracy.

During the scanning process, if the data tracking is lost, how can it be recovered?

For hybrid alignment:

Causes:

- Scanner moved too quickly, resulting in insufficient feature overlap between frames

- Improper scanning distance (too close/far), causing feature recognition failure by the cameras

Solutions:

- Return to a previously scanned area while maintaining the optimal scanning distance

- Pause for 2 seconds to allow the scanner to recognize features and re-establish alignment

Note:

- Begin with feature-rich areas for the first frame to establish a strong reference.

- Pause scanning if alignment fails for >5 seconds, reposition the scanner topreviously captured areas with clear features and resume scanning.

For marker mode:

Causes: Insufficient markers / Marker degradation / Overly regular marker arrangement

Solutions:

- Add several markers in sparse areas and continue scanning, though with reduced positional accuracy. For better results, initiate a new scan with properly distributed markers.

- Remove worn-out markers with alcohol swabs, and replace with new ones.

- Rearrange the existing markers to avoid overly regular placement.

When is it necessary to stick markers when scanning with hybrid alignment?

For objects with limited geometric features and uniform coloration (e.g., car doors), markers must be applied to featureless areas (e.g., flat surfaces) to facilitate scanning and alignment.

Note: To scan objects using markers with hybrid alignment, enable the Laser Fill Light in Scan Mode > Settings > Switch

How to choose appropriate scanning modes in 3DeVOK Studio scanning software?

For objects scanned with 3DeVOK MT/MQ, the primary classifications and suggested scanning modes are listed below:

- Matte/textured/multi-colored objects:Laser Scan – Hybrid Alignment / Infrared Structured Light Scan

- Large-scale objects(>30cm): Infrared Structured Light Scan / Marker Alignment

- Human:Human Mode / Lightless Scan

- Glossy black/reflective/detailed components:Laser Scan – Marker Alignment

- Small parts(5-10cm): Laser Scan – Marker Alignment

After finishing the scanning of markers, why does the scanner continue to capture marker points rather than scanning the object?

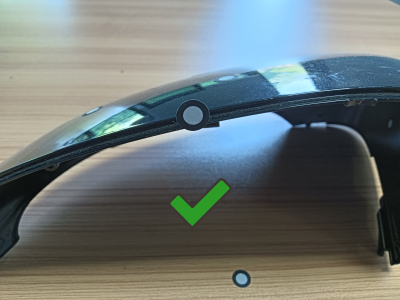

After scanning the markers, click Finish in the software or long press the button on the touchscreen and wait for the green progress circle to complete one full rotation. Release your finger when it turns into a green √ (as shown in the image below) to finish scanning markers. Then click “Start” to scan the object.

What should be noticed when sticking markers?

- Markerplacement: When sticking markers, each marker should be positioned more than 3mm away from the edges or features to ensure the hole-filling algorithm works properly. Otherwise, the marker area may not be filled correctly, affecting the quality of the edge data.

- Distance between markers: The distance between any two points should not exceed 10-12 cm, with 6-8 cm being recommended.

- Marker position: Markers should be stuck on a flat surfaceinstead of a corner or a

For reflective objects with few features, how to handle the issue of Assist Patterned Pad reflecting onto the object during photography?

You can print the Assist Patterned Pad provided on the official website, cut it into the shape shown below according to the real size of object. Then place it on the turntable for photography.

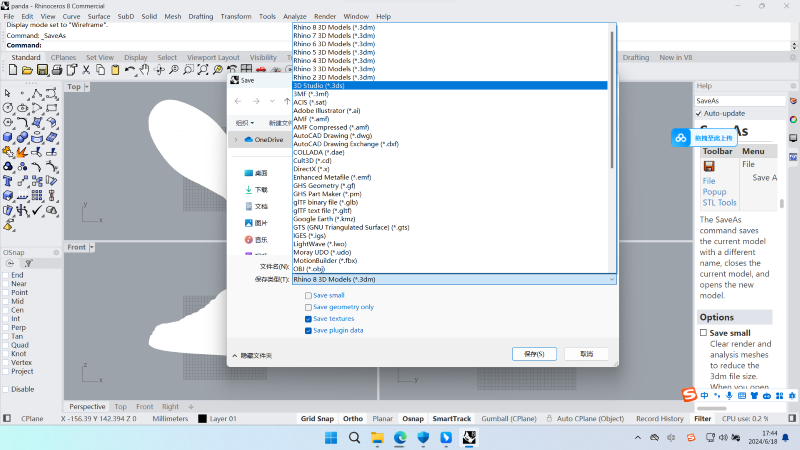

How can an obj file obtained from an 3DeVOK Studio Scanning Software be imported into SketchUp (SU) software and opened?

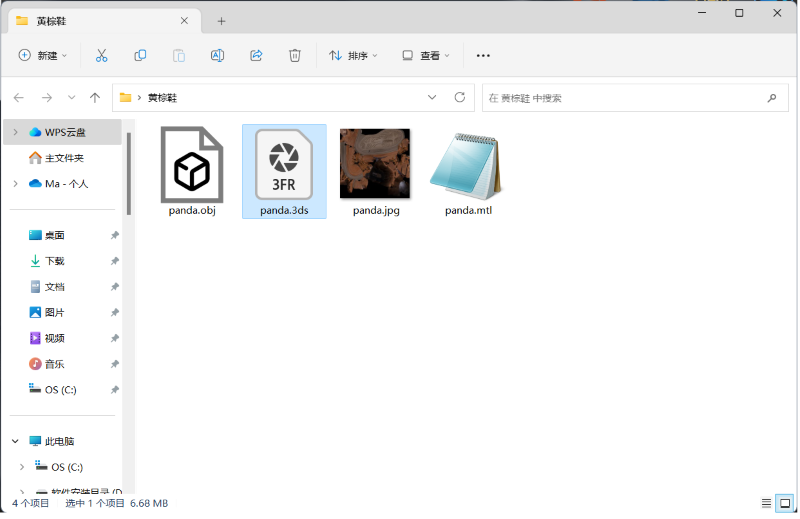

Color 3D models exported from 3DeVOK Studio scanning software usually consist of obj (mesh), mtl (material), and jpg (texture) files. The obj file can be imported into 3D software (e.g., Rhinoceros), saved as a *.3ds format, and then exported.

Next, import the *.3ds file into SU.

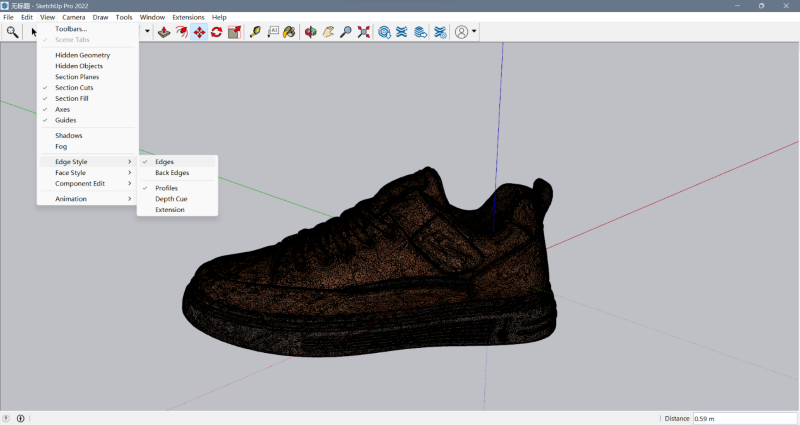

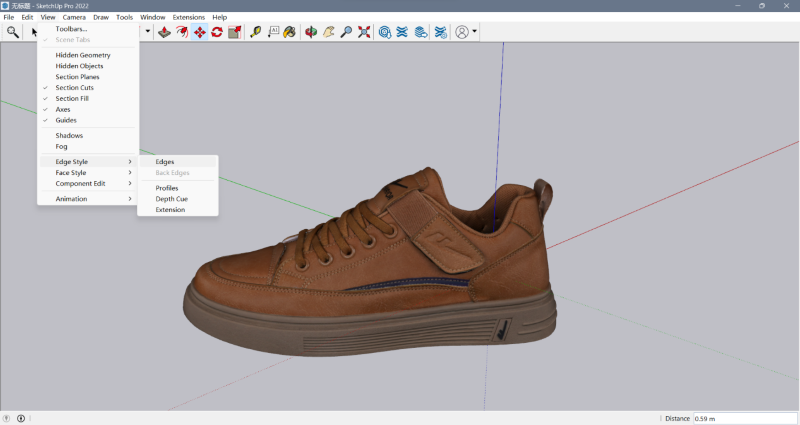

To hide the edge lines in the imported file, click View – Edge Style – Edges and uncheck the box.

How to improve 3D scanning accuracy in reflective marker splicing mode (Landmark)?

5. An appropriate 3D scanning distance is also conducive to improving accuracy. In the optimal scanning distance range, scan a little farther away, which can recognize more reflective markers, thus improving the accuracy.

6. Diffuse reflective surfaces help ensure the quality of the 3D reconstruction point cloud. The reflection/refraction of laser/scattering on the object’s surface can increase reconstruction errors. For example, the reconstructed sphere diameter of a translucent sphere may be smaller than the original one. Therefore, for highly reflective, specular, transparent, translucent, black and challenging surfaces, applying a contrast enhancer can help ensure the quality of the 3D point cloud reconstruction.

Summary of Precautions for Pasting reflective markers:

1. The more irregular the reflective marker, the higher the accuracy.

2. Reflective markers should be scattered and placed on all directions and heights of the items to be scanned.

3. The distance between two reflective markers should be 4-8 cm for optimal accuracy.

4. The distance between the plane of the reflective marker and each feature of the item being scanned should be no more than 25 mm.

5. Reflective markers should not be placed on important geometric features or edges to prevent data loss. Instead, place them on large surfaces/planes whenever possible.

Note: If the 3D scanning accuracy requirement is not stringent, the above guidelines can be followed selectively.

After the data is saved, re-open the file in the 3DeVOK Studio software, the next step cannot be processed.

- Check whether the datanumber in the DataImage folder where the scanning project is saved is continuous. If there are intermittent numbers, the data cannot be processed normally.

- At the same time, check whether there are files of 0 kb in the folder. Those files will also affect the normal processing of data.

- Check the performance of the CPU and GPU of the computer and check if the disk space of the computer is sufficient, you can quickly check them from the diagnosis function of the software.