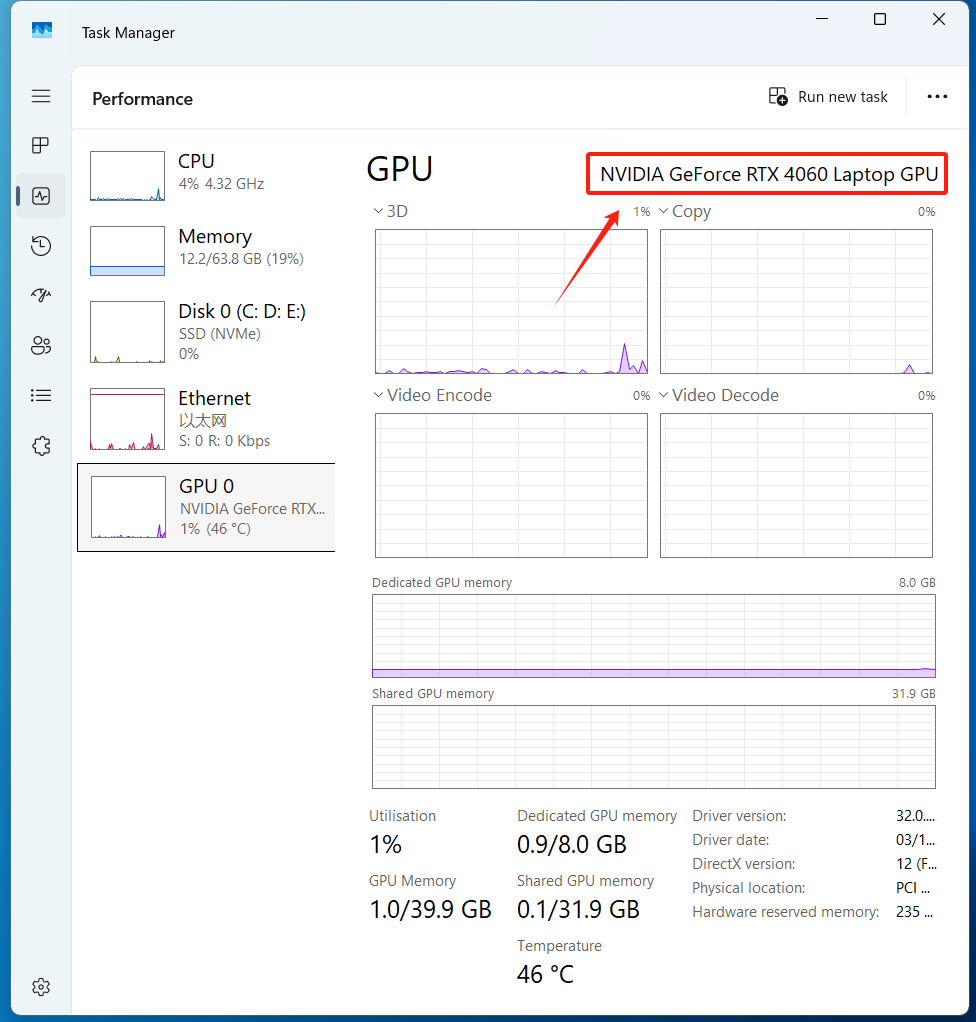

After installing the software, when starting it, a prompt appears stating **the reason for the missing ‘nvml.dll’ file**

- First, check if the computer meets the requirements of NVIDIA dedicated graphics card Task Manager – Performance -GPU (Generally, dedicated graphics cards are GPU1, so check GPU1 first. If there is no GPU1, then look at GPU0).

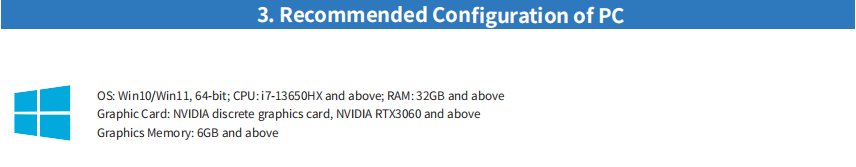

If there is no NVIDIA dedicated graphics card, the computer configuration needs to be The recommended configuration is as follows:

Under the condition of having a NVIDIA independent graphics card that meets the requirements, the reasons for the absence of the dll file are as follows:

① The driver was not installed or updated correctly.

② The operating system files were damaged.

③ The system files were lost due to virus or malicious software attacks.

④ The user manually or through certain cleaning software mistakenly deleted the key system files.

The nvml.dll file needs to be installed manually or imported.

During the scanning process, if the data tracking is lost, how can it be recovered?

For hybrid alignment:

Causes:

- Scanner moved too quickly, resulting in insufficient feature overlap between frames

- Improper scanning distance (too close/far), causing feature recognition failure by the cameras

Solutions:

- Return to a previously scanned area while maintaining the optimal scanning distance

- Pause for 2 seconds to allow the scanner to recognize features and re-establish alignment

Note:

- Begin with feature-rich areas for the first frame to establish a strong reference.

- Pause scanning if alignment fails for >5 seconds, reposition the scanner topreviously captured areas with clear features and resume scanning.

For marker mode:

Causes: Insufficient markers / Marker degradation / Overly regular marker arrangement

Solutions:

- Add several markers in sparse areas and continue scanning, though with reduced positional accuracy. For better results, initiate a new scan with properly distributed markers.

- Remove worn-out markers with alcohol swabs, and replace with new ones.

- Rearrange the existing markers to avoid overly regular placement.

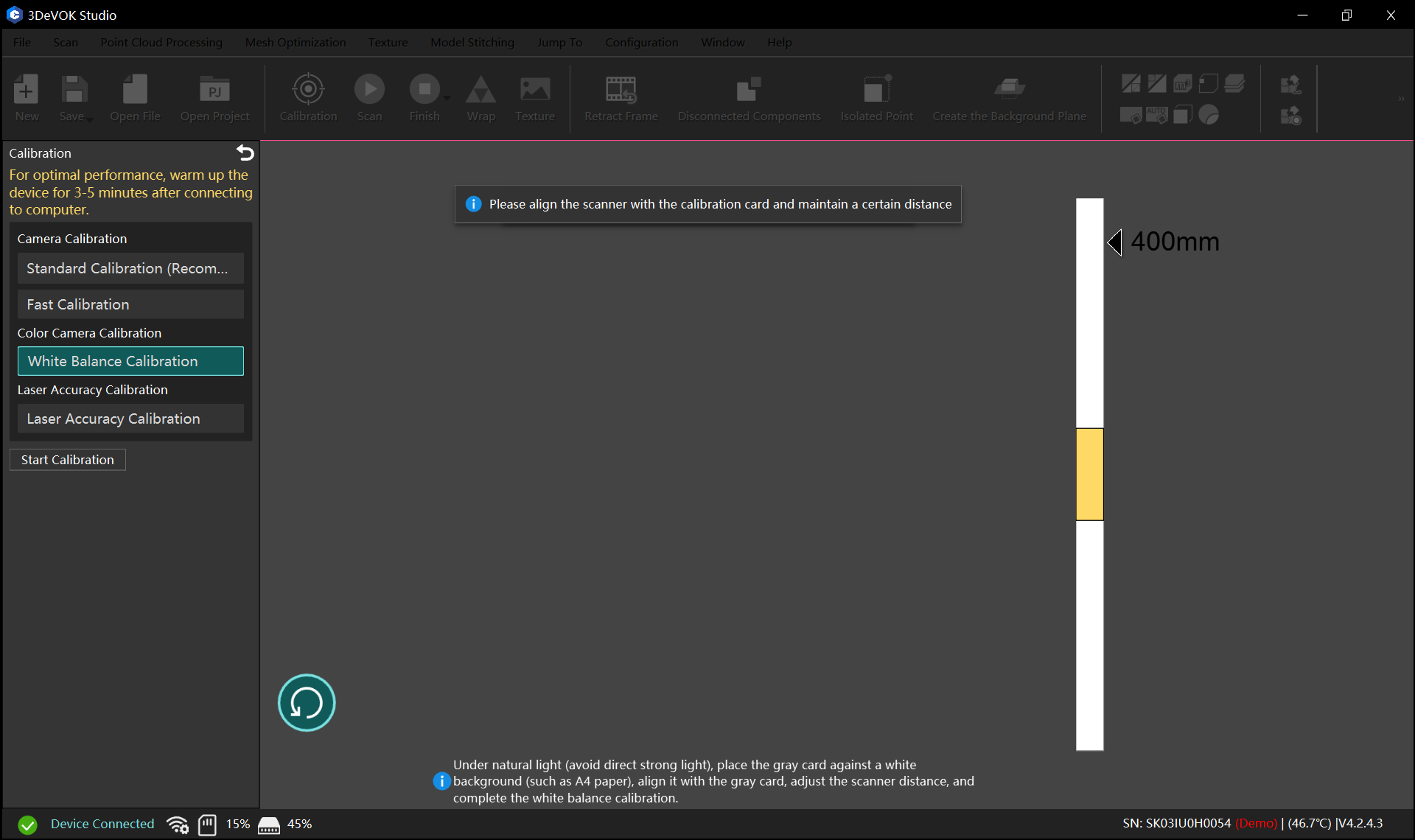

How to perform white balance calibration?

The method and steps for calibrating white balance are as follows:

- Take out the gray card from the case and position it face-up on a light-color surface.

- Select the “White Balance Calibration ” function on the left, and process the calibration following the on-screen instructions, as shown in Figure 6-3.

- Align the scanner perpendicularly to the gray card surface, adjust the distance until the position indicator enters the yellow target frame on the user interface.

- Maintain a vertical standoff distance of 300 mm between the scanner and the gray card.

- Environmental Change Between Scans (e.g., outdoor-to-indoor transition).

- Color Deviations (e.g., significant hue/saturation deviation during real-time preview)

- Complex Ambient Lighting (e.g., Mixed artificial light sources (e.g., red/green dominant illumination)

How to Ensure High-Speed Point Cloud 3D Reconstruction During Scanning with 3DeVOK device?

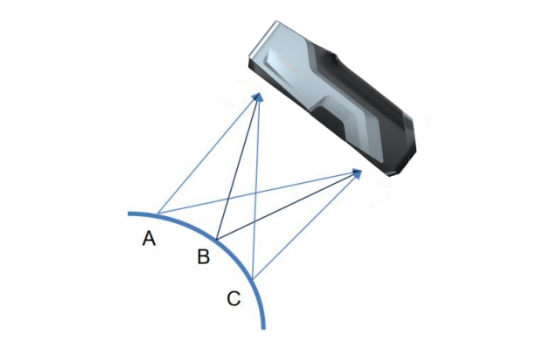

The dual black-and-white cameras are mounted at a specific angle to each other, and the optimal scanning angle occurs when both cameras can detect the target object at near-vertical incidence angles. Point B yields the highest point cloud density, while points A and C produce the sparsest data. For challenging areas or dead zones, the scanner can be re-positioned to ensure simultaneous object visibility by both cameras.

For optimal scanning results, maintain a working distance between 200mm and 400mm to achieve the highest point cloud quality and finest detail resolution.

Optimal scanning distance of Infrared Structured Light Scan: 300 mm

Optimal scanning distance of Infrared Laser: 300 mm

Optimal scanning distance of Blue Laser: 210 mm

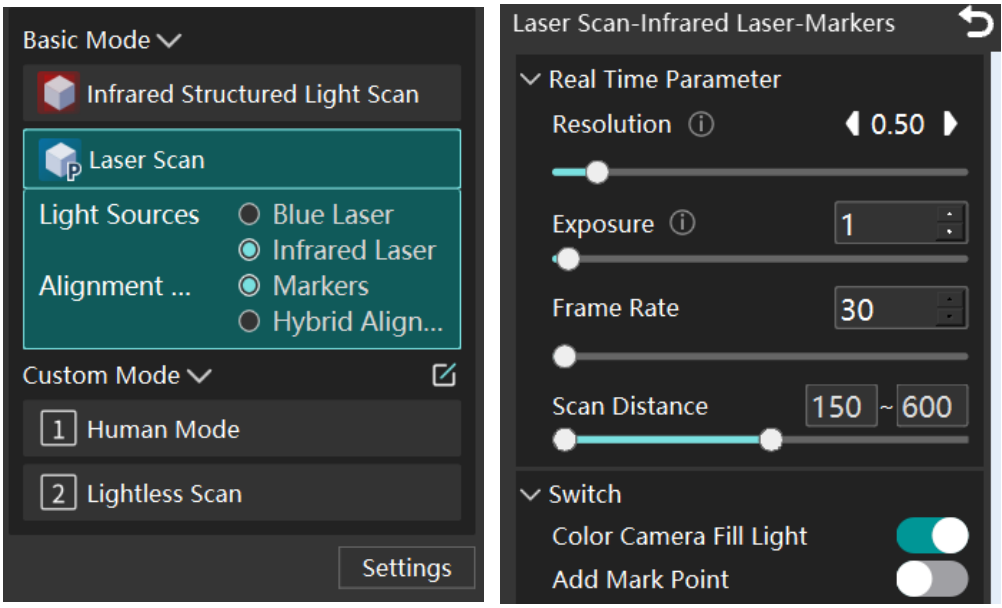

How to Scan a Color Model Using Infrared Marker Mode in 3DeVOK Studio scanning software?

Select Infrared Laser and Marker Mode in scanning mode, and click settings to enable Color Camera Fill Light. When the option is turned on, the maximum scanning frame rate will drop from 70 FPS to 30 FPS.

When is it necessary to stick markers when scanning with hybrid alignment?

For objects with limited geometric features and uniform coloration (e.g., car doors), markers must be applied to featureless areas (e.g., flat surfaces) to facilitate scanning and alignment.

Note: To scan objects using markers with hybrid alignment, enable the Laser Fill Light in Scan Mode > Settings > Switch

What is the mechanism of hybrid alignment of 3DeVOK MT/MQ?

This advanced mode enables simultaneous recognition of:

- Geometric features(surface contours/edges)

- Texture features(natural patterns)

- Markers(when applied)

The hybrid alignment mode improves scanning performance through:

- Enhanced alignment accuracy

- Reduced marker dependency(enabling scans with:

- Zero markers for textured objects

- 3-5 markers for low-feature surfaces)

What is the difference between blue laser and infrared laser in 3DeVOK MT device?

- Visibility & User Experience:

Infrared lasers operate in the non-visible spectrum, while blue light is visible. This makes infrared scanning more user-friendly (e.g., no glare or visual disturbance). - Material Adaptability:

Blue light is prone to absorption by red/yellow objects, rendering it unsuitable for scanning such surfaces. Infrared exhibits superior penetration and reflection consistency across colors. - Detail Resolution:

Blue light achieves marginally higher detail accuracy, making it ideal for high-precision applications. - Scanning Speed:

With a higher laser line density (34 beams vs. 22 beams), blue light enables faster scanning compared to infrared.

How to choose appropriate scanning modes in 3DeVOK Studio scanning software?

For objects scanned with 3DeVOK MT/MQ, the primary classifications and suggested scanning modes are listed below:

- Matte/textured/multi-colored objects:Laser Scan – Hybrid Alignment / Infrared Structured Light Scan

- Large-scale objects(>30cm): Infrared Structured Light Scan / Marker Alignment

- Human:Human Mode / Lightless Scan

- Glossy black/reflective/detailed components:Laser Scan – Marker Alignment

- Small parts(5-10cm): Laser Scan – Marker Alignment

After finishing the scanning of markers, why does the scanner continue to capture marker points rather than scanning the object?

After scanning the markers, click Finish in the software or long press the button on the touchscreen and wait for the green progress circle to complete one full rotation. Release your finger when it turns into a green √ (as shown in the image below) to finish scanning markers. Then click “Start” to scan the object.

What should be noticed when sticking markers?

- Markerplacement: When sticking markers, each marker should be positioned more than 3mm away from the edges or features to ensure the hole-filling algorithm works properly. Otherwise, the marker area may not be filled correctly, affecting the quality of the edge data.

- Distance between markers: The distance between any two points should not exceed 10-12 cm, with 6-8 cm being recommended.

- Marker position: Markers should be stuck on a flat surfaceinstead of a corner or a

Why does the device suddenly generate noise data during scanning?

It is caused by an excessive temperature difference between device calibration and the actual scanning environment. If the temperature difference exceeds 8°C, recalibration is required.

If there is no NVIDIA dedicated graphics card, the computer configuration needs to be The recommended configuration is as follows:

If there is no NVIDIA dedicated graphics card, the computer configuration needs to be The recommended configuration is as follows: