What are the differences between handheld and desktop 3D scanners? What applications or scenarios is each type best suited for?

Handheld 3D scanners are more flexible and are ideal for scanning complex or large objects, while desktop 3D scanners are more stable and better suited for small objects that require high-precision scanning.

Handheld 3D scanners, such as the 3DeVOK MT and MQ, are operated by the user holding the device during scanning. They offer high flexibility and are especially suitable for complex parts and on-site scanning scenarios where the object cannot be moved. They are widely used in artistic design, reverse engineering, 3D measurement, 3D visualization and display, 3D printing, scientific research, and education, etc.

Desktop 3D scanners use a fixed scanning system combined with an automatic turntable to complete the scanning process. They provide higher stability and are more suitable for high-accuracy scanning of small and precise parts. They are commonly used for quality inspection, product design, and artwork modeling, etc.

What is the resolution of the 3DeVOK MT scanner? Does the resolution affect the level of detail in the final 3D model?

The MT offers three different light source modes: Blue Laser, Infrared Laser, and Infrared Structured Light . Each mode supports different adjustable resolution.

Blue Laser: 0.05–5 mm (adjustable in 0.05 mm increments)

Infrared Laser: 0.1–5 mm (adjustable in 0.1 mm increments)

Infrared Structured Light: 0.1–5 mm (adjustable in 0.1 mm increments)

Different resolution settings will affect the level of detail in the final 3D model.

Generally speaking, a resolution of 0.2–0.3 mm is sufficient to capture enough detail for most applications. The smaller the resolution, the finer the details, but the point cloud processing time will also be longer.

How fast is the scanning speed of the 3DeVOK MT scanner? How long does it take to scan an object?

The MT offers three different light source modes: Blue Laser, Infrared Laser, and Infrared Structured Light.

Each mode has a different point cloud acquisition speed:

- Blue Laser:up to 3,300,000 points/sec

- Infrared Laser:up to 2,450,000 points/sec

- Infrared VCSEL Structured Light:up to 4,500,000 points/sec

The actual scanning time depends on the object size, selected light source mode, point spacing, scanning frame rate, and other settings.

Typical scanning time examples:

Scanning a human torso (spine area): approx. 1 minute

(Light source: Infrared Structured Light; Alignment : Geometry; Resolution: 1.0)

Scanning an artwork (20–30 cm): approx. 2 minutes

(Light source: Blue Laser; Alignment : Texture + Geometry; Resolution: 0.7)

When using the 3DeVOK scanner with the wireless handle for scanning, what is the battery life?

With the standard Nitecore NL2160 6000mAh batteries, two batteries provide approximately 2 hours of continuous operation.

What are the dimensions of the 3DeVOK MT waterproof case and the 3DeVOK MQ outer case?

The 3DeVOK MT waterproof case measures 358×284×168mm, and the 3DeVOK MQ outer case measures 280×260×108mm.

How many reflective markers are included in the 3DeVOK MT and 3DeVOK MQ scanner accessories?

The set includes 2000 pieces of 6mm reflective markers and 500 pieces of 3mm reflective markers.

What is distinction between Laser ClassⅠ and ClassⅡ ?

ClassⅠ Lasers are classified as inherently safe. Direct beam viewing, including with the use of optical aids, will not result in injury. Safety is achieved through engineering design and protective housing (for instance, a high-power laser source is fully contained, allowing only non-hazardous radiation leakage).

ClassⅡ Lasers are classified as conditionally safe. Their safety is dependent upon the natural aversive response (blink reflex) of the eye. While an inadvertent exposure is within safe limits, deliberate fixation on the beam presents a risk of retinal damage.

What is distinction between Laser ClassⅠ and ClassⅡ ?

ClassⅠ Lasers are classified as inherently safe. Direct beam viewing, including with the use of optical aids, will not result in injury. Safety is achieved through engineering design and protective housing (for instance, a high-power laser source is fully contained, allowing only non-hazardous radiation leakage).

ClassⅡ Lasers are classified as conditionally safe. Their safety is dependent upon the natural aversive response (blink reflex) of the eye. While an inadvertent exposure is within safe limits, deliberate fixation on the beam presents a risk of retinal damage.

What is thermal equilibrium of the 3DeVOK scanner? Why is it important?

Thermal equilibrium for the 3DeVOK scanner is the stable state it reaches after warming up, where its internal temperature stabilizes. This is critical for ensuring the scanner’s highest measurement accuracy.

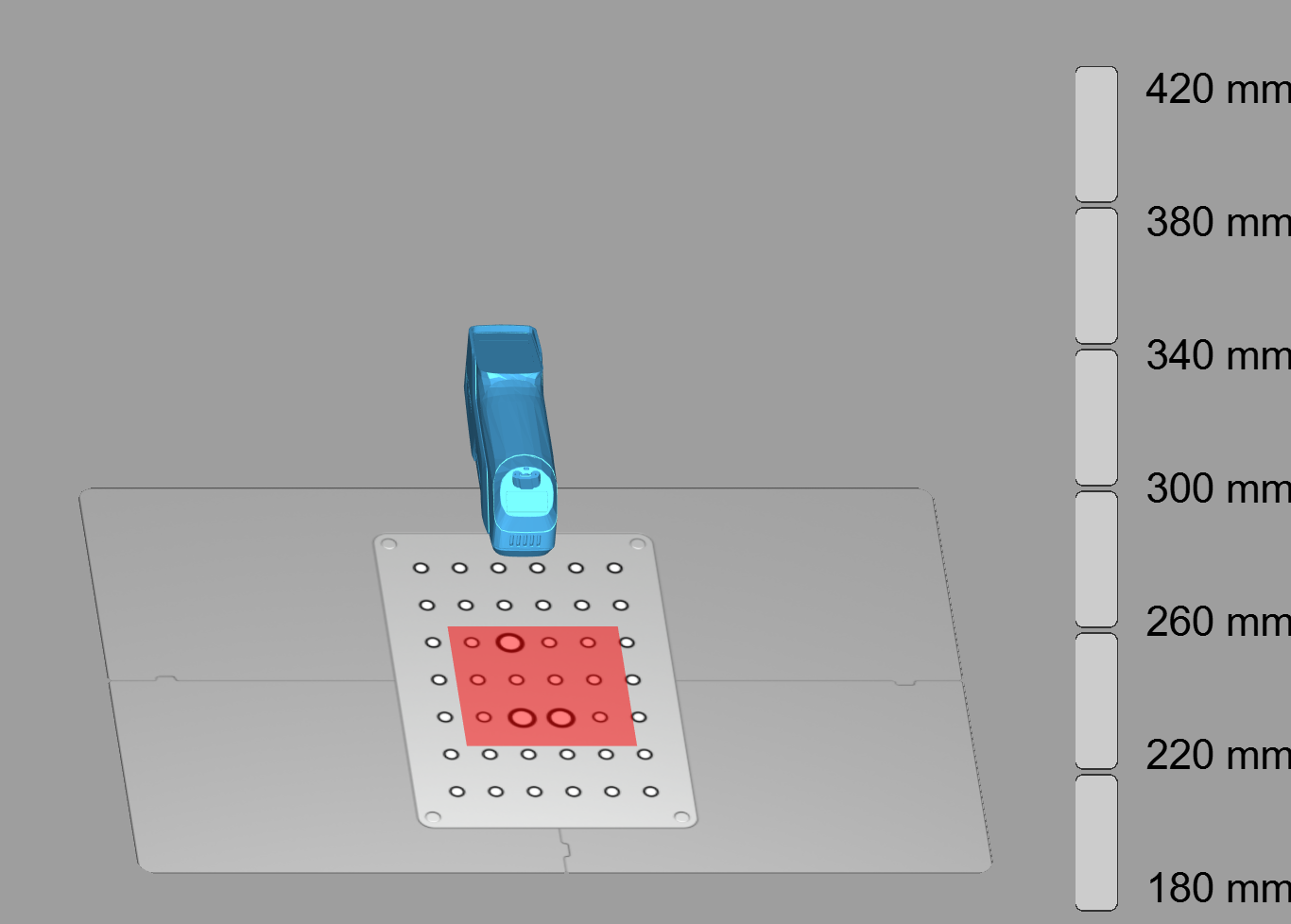

Why does the 3DeVOK MT standard calibration require 4 expansion accessories?

The first six steps of the standard calibration involve calibrating the laser lines. When the scanner is raised to a certain height, the laser lines on the edges may extend beyond the master plate, causing the laser lines to disconnect. To address this issue, the 4 expansion accessories is used as an accessory to ensure proper calibration.

How to Ensure High-Speed Point Cloud 3D Reconstruction During Scanning with 3DeVOK device?

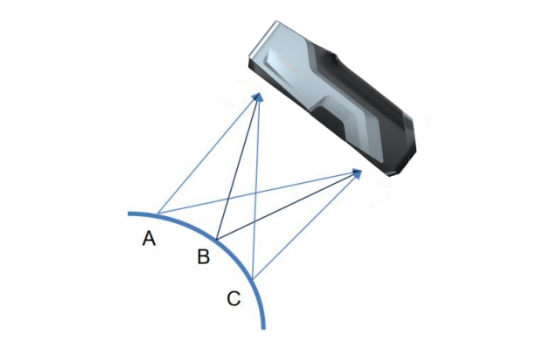

The dual black-and-white cameras are mounted at a specific angle to each other, and the optimal scanning angle occurs when both cameras can detect the target object at near-vertical incidence angles. Point B yields the highest point cloud density, while points A and C produce the sparsest data. For challenging areas or dead zones, the scanner can be re-positioned to ensure simultaneous object visibility by both cameras.

For optimal scanning results, maintain a working distance between 200mm and 400mm to achieve the highest point cloud quality and finest detail resolution.

Optimal scanning distance of Infrared Structured Light Scan: 300 mm

Optimal scanning distance of Infrared Laser: 300 mm

Optimal scanning distance of Blue Laser: 210 mm

What is the mechanism of hybrid alignment of 3DeVOK MT/MQ?

This advanced mode enables simultaneous recognition of:

- Geometric features(surface contours/edges)

- Texture features(natural patterns)

- Markers(when applied)

The hybrid alignment mode improves scanning performance through:

- Enhanced alignment accuracy

- Reduced marker dependency(enabling scans with:

- Zero markers for textured objects

- 3-5 markers for low-feature surfaces)