3D Data Acquisition Device: TrackScan-P42 3D System

Data Processing Software: 3DeVOK Mapping Software and Photoshop

3D Scanning with TrackScan-P42

1. 3D Scanning with TrackScan-P42

With Scantech’s TrackScan-P42 3D system, which is non-contact and portable, inscriptions can be scanned without markers. This method achieves high-precision 3D data with accuracy up to 0.02mm, capturing detailed white model data.

2. Selecting Optimal Scanning Resolution

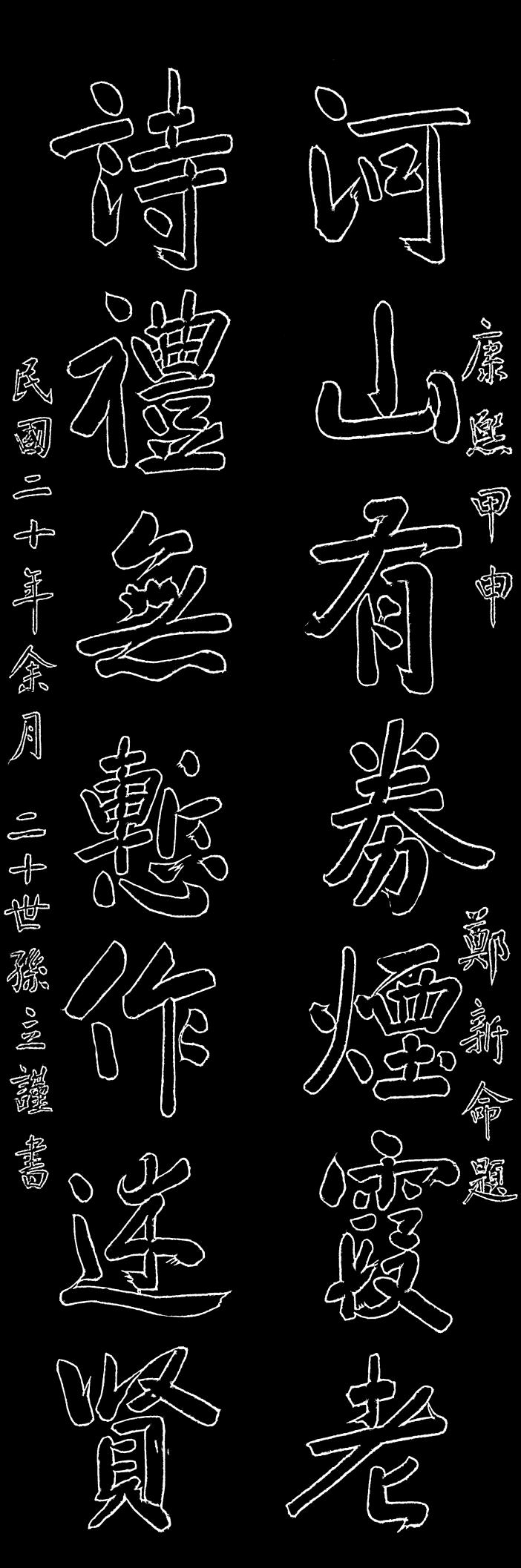

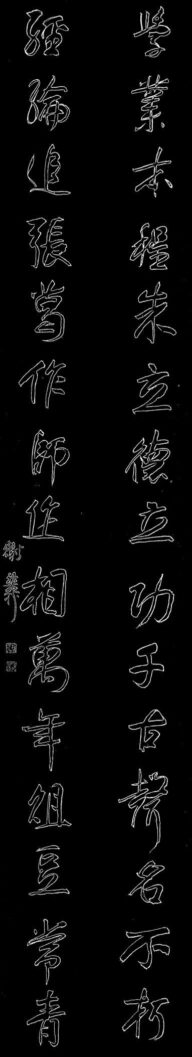

The best 3D scanning resolution is chosen based on the inscription’s size. The system can achieve a resolution as fine as 0.02mm. This ensures the edge curves of each character and inscription details are accurately replicated in their original dimensions. Below is an example of the 3D scanning data:

3. Data Processing in 3DeVOK Mapping Software

The scanned data is imported into 3DeVOK mapping software. Utilizing OpenGL pipeline technology, the software enhances the rendering of normal gradients and depths of triangular meshes to produce high-resolution black-and-white rubbings. The closer the points in the point cloud, the more precise the edge details and the more realistic the rubbing.

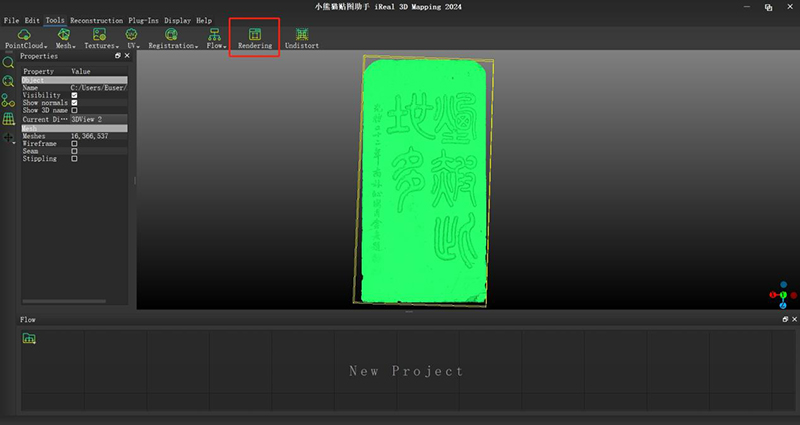

(1) Import the file into 3DeVOK mapping software. Select the model and click “Rendering.”

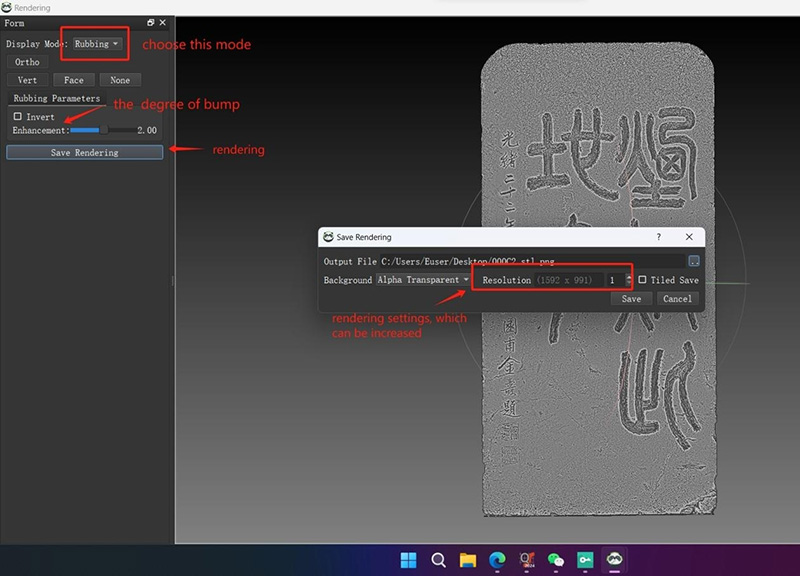

(2) Choose the “Rubbing Mode,” adjust the enhancement factor, and save the rendering. The resolution can be set, and export formats include JPG, PNG, TIFF, and other common image formats.

(3) Use Photoshop to process the image and filter out noise. This results in a refined black-and-white image.

Other rubbings: