iReal 2E, a professional-grade handheld 3D scanner, has four alignment modes: feature alignment, texture alignment, mixed alignment and marker alignment. Users can choose the most suitable mode according to different situations.

Since the first three alignment modes mainly rely on geometric/texture features to finish the splicing, the alignment accuracy will depend on the richness of the surface features, scanning technique, and scanning path.

For example, in the case of scanning items of the same length with the same geometric features, one is a flat engraving (the scanning path cannot form a closed loop) and the other is a three-dimensional engraving (the scanning path can form a closed loop), the accuracy of the geometric feature splicing is about 1 mm/m and 0.3 mm/m respectively.

Given the first three alignment modes, all have strong uncertainty in terms of accuracy and consistency, therefore, when encountering situations with high accuracy requirements (such as reverse engineering design), it is often necessary to use the marker alignment mode (relying on a certain number of marker points pasted on/around the surface of the scanned object to perform data splicing), which can ensure that the alignment accuracy is stable within 0.3 mm/m.

Here we verify the accuracy of our handheld structured light scanner – iReal 2E under the marker alignment mode by testing the following four application scenarios.

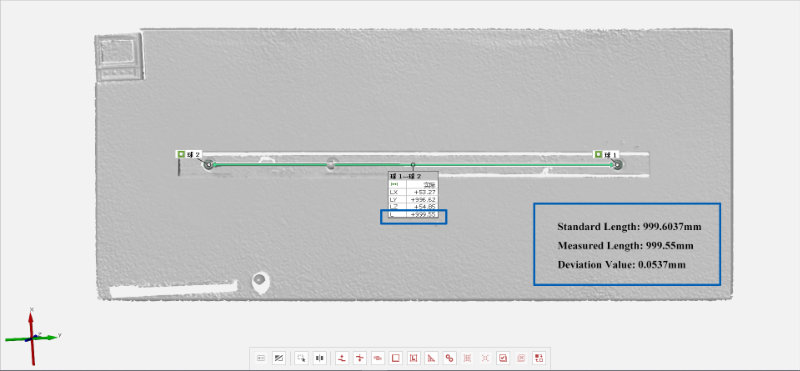

Test 1: Standard Length Part Calibration

Under the marker alignment mode, scan the standard length part, and the deviation of the spherical center distance between the acquired spheres from the standard value is the splicing error value (accuracy value). This is a more general way to test length accuracy for 3D scanners.

As shown in the figure below, when scanning this 999.6037 mm part, the 3D data of two standard spheres were obtained by iReal 2E scanning, and then the spherical centers of the two spheres were fitted by GOM Inspect 3D inspection software, which in turn calculated the two spherical center distance to be 999.55 mm with a deviation value of 0.0537 mm.