Reverse Engineering

In the field of reverse engineering, 3D digitization is the process of creating a digital model of an existing physical object. This process can be used to create a virtual copy of an object for various purposes, such as analysis, design, or manufacturing.

Reverse engineering is the process of taking an existing product and deconstructing it in order to understand its design, functionality, and manufacturing process. This information can then be used to improve the product or to create a new one. In the past, reverse engineering was a time-consuming and expensive process that required the physical disassembly of the product. But thanks to advances in 3D digitization, it can now be done quickly and relatively cheaply.

The application of 3D digitization in reverse engineering has been developed quite well. The 3D scanner offered by 3DeVOK supports up to 0.02 mm of accuracy and can be used as a one-stop mechanical solution in a cost-effective way. Our handheld 3D scanner and 3D scanning software allow users to accurately and effortlessly analyze and re-design a product or a part with CAD and CAM programs, for which they benefit in multiple industries, such as manufacturing, construction, and even healthcare.

3DeVOK 3D Scanner

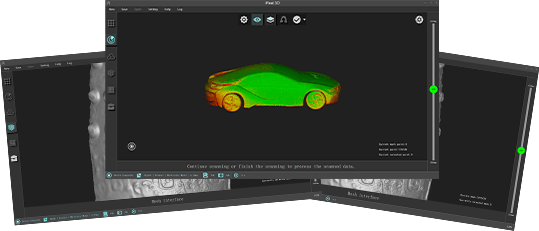

Accelerate Automotive Design with 3DeVOK 3D Scanning Solutions

From reverse engineering to rapid prototyping and virtual simulations, 3DeVOK 3D scanners offer fast, accurate solutions for every stage of automotive design and inspection. Case 1 – Whole Vehicle Scanning with 3DeVOK MT for 3D Visualization The 3DeVOK MT 3D scanner, featuring a 34-line blue laser and marker alignment mode, delivers up to 0.04 mm accuracy. With […]