In today’s dynamic automotive industry, achieving precision, efficiency, and innovation is paramount for success. From design and rapid prototyping to reverse engineering and virtual assembly, 3D scanners have seamlessly integrated into automakers’ technological arsenals. They have become indispensable tools that accelerate daily productivity and condense development cycles, enabling the creation of high-performance vehicles without compromising safety or quality standards.

3DeVOK scanning technology exemplifies this transformative trend by swiftly digitizing car parts in 3D with high accuracy. This capability has revolutionized operations across the automotive sector, spanning from design and prototyping to customization and performance enhancement.

The automotive applications include reverse engineering, rapid prototyping, 3D visualization, virtual simulations, digital archives, design, inspection and quality control, etc.

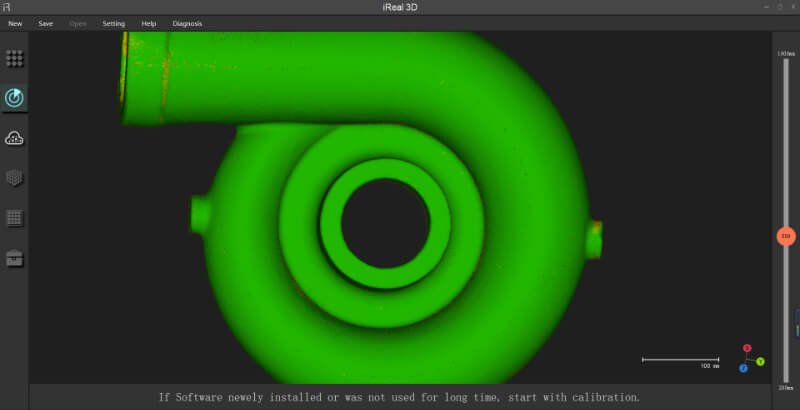

Introducing the iReal M3 dual-infrared laser 3D scanner, engineered with two light sources for unparalleled precision. Its Infrared Laser Scanning Mode excels on dark and reflective surfaces, making it ideal for automotive parts and other challenging environments to more accurate and complete 3D data with sharper edges.

If you’re interested in checking out the data results captured by our two distinct scanners, dive into our latest blog post What’s the Difference between iReal M3 and iReal 2E?

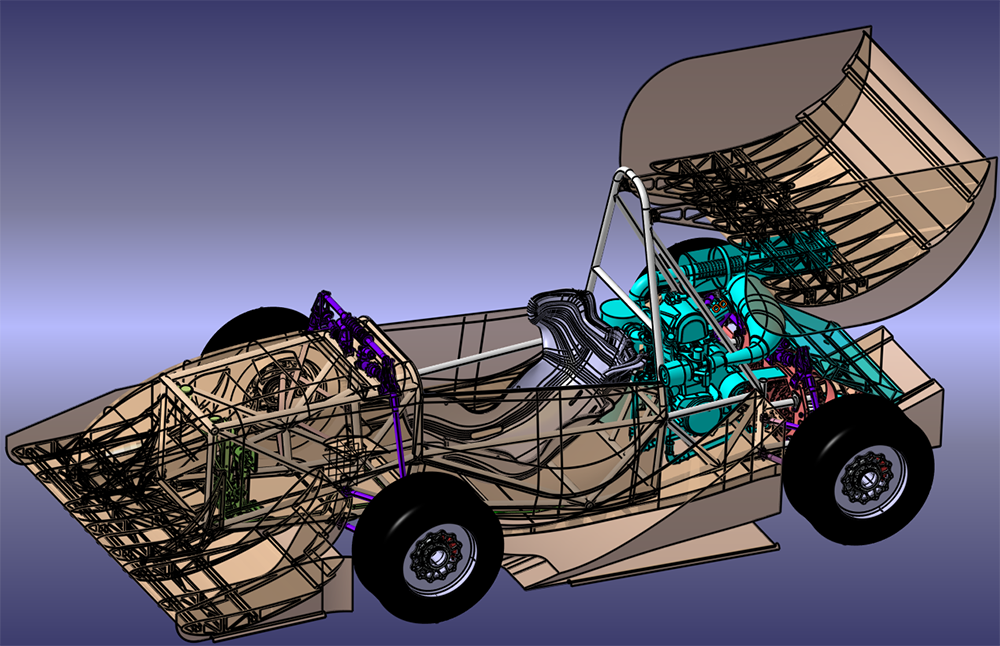

Reverse Engineering

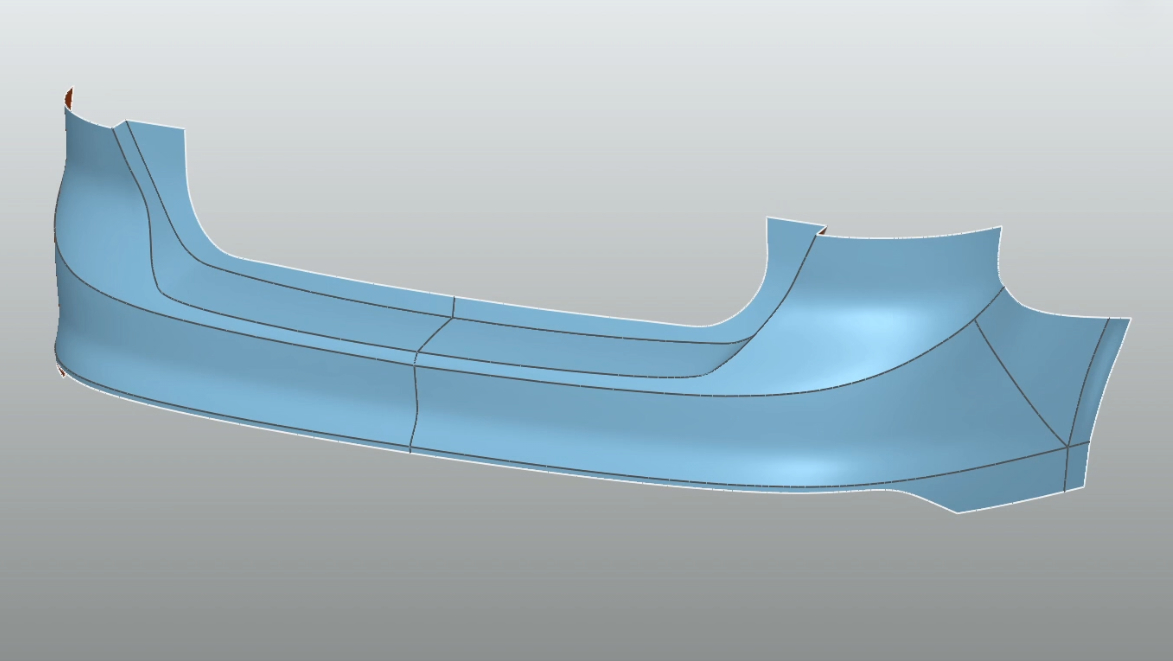

3D scanning offers a rapid way to accurately capture automotive parts that may lack documentation or are no longer in production, capturing complex surfaces and detailed structures. The scanned data can then be used to create functional CAD models for further analysis and product development in QUICKSURFACE or Geomagic Design X reverse engineering software.

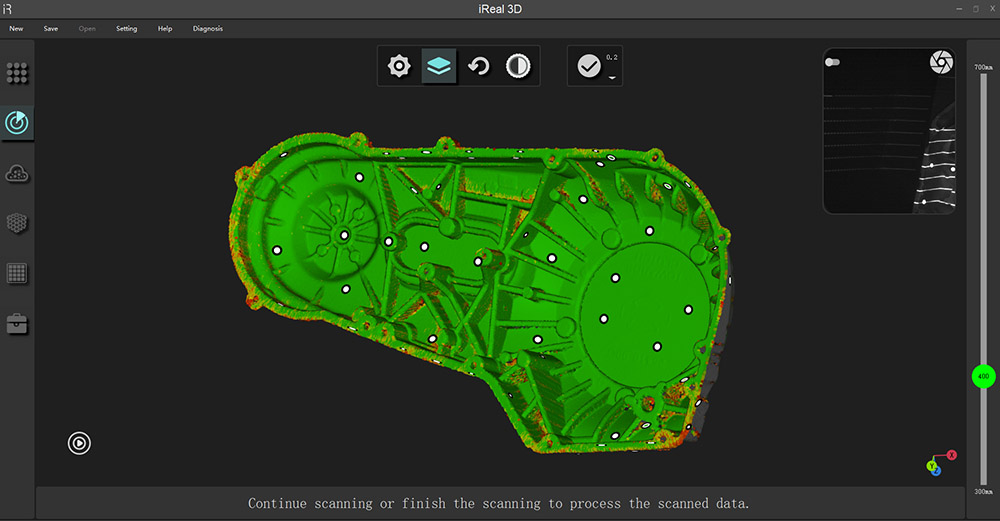

iReal 3D Scanned Data

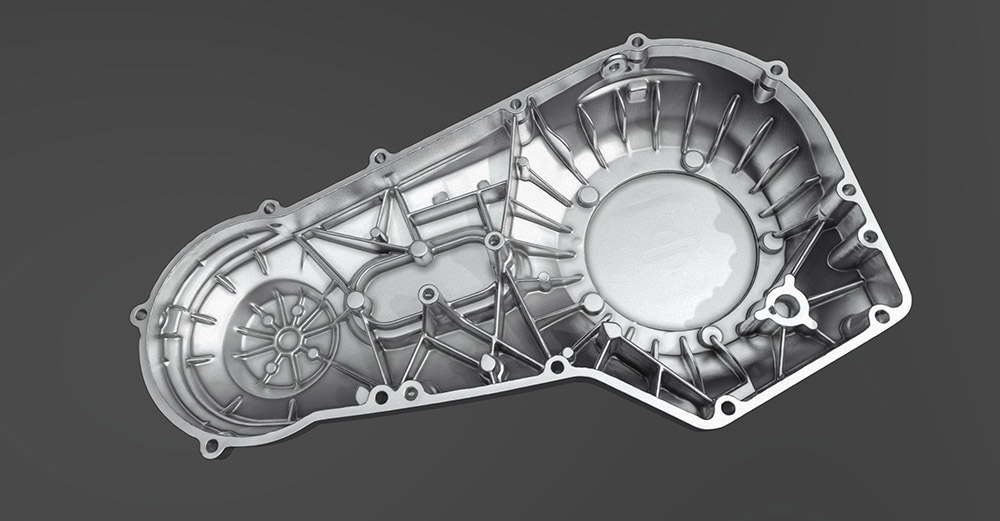

3DeVOK Scanned Data

CAD Data of the Car Bumper

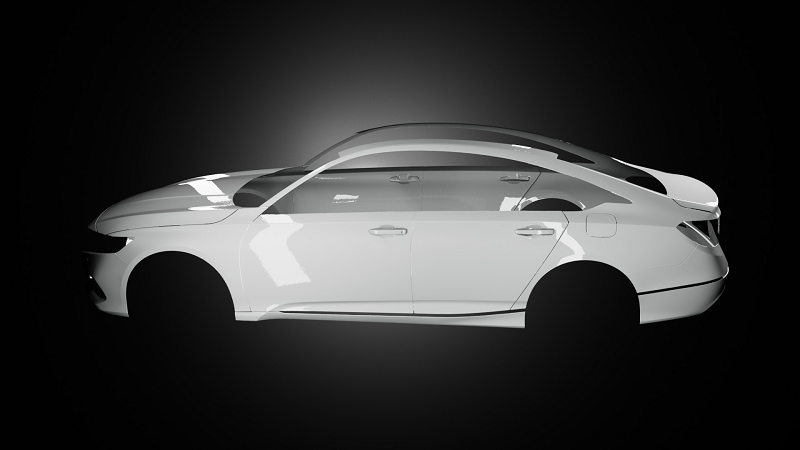

3D Visualization

Create immersive experiences using 3D scanners and 3DeVOK Mapping software to capture both the interiors and exteriors of cars, enabling the effortless creation of VR-ready 3D models. This allows your customers the freedom to explore these virtual vehicles from anywhere, replicating the experience of a traditional car dealership visit.

3DeVOK Mapping software, a texture-making software compatible with all brands of 3D scanners, harnesses images and scanned data to generate precise and photorealistic 3D models.

Realistic 3D Model in 3DeVOK Mapping Software

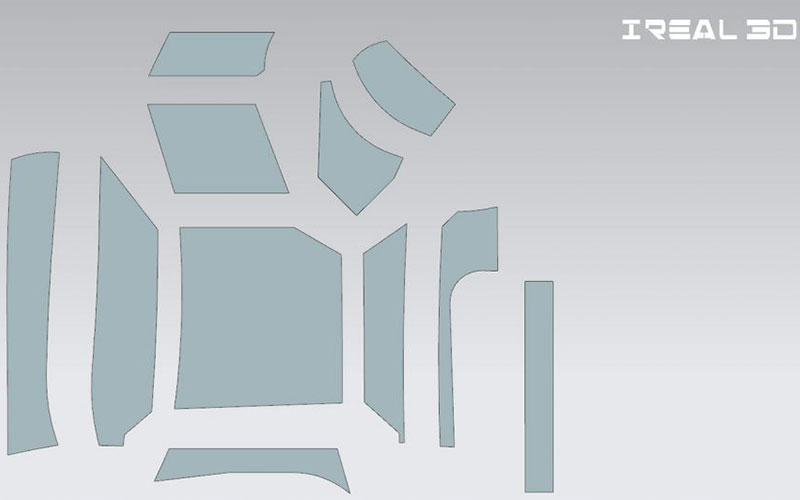

Vehicle Customization / Design for Aftermarket Auto Parts

Numerous vehicle owners opt to personalize their vehicles with custom parts and accessories that serve various functional and aesthetic needs. Utilizing 3D scanning technology ensures aftermarket parts fit with unparalleled precision, from car floor mats to seat covers and beyond.

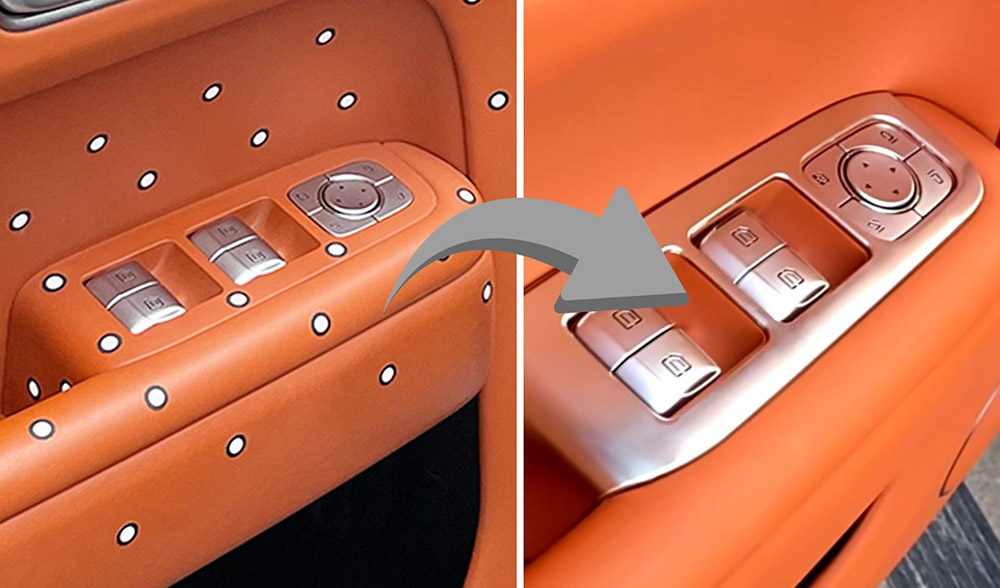

Case Study in Automotive Aftermarket

The iReal M3 dual-infrared 3D scanner showcases its capabilities by scanning the window switch control panel of the Li Auto L8. This precise 3D data enables manufacturers to craft protective kits that snugly fit your vehicle’s contours, delivering optimal coverage and safeguarding while meeting your unique preferences.