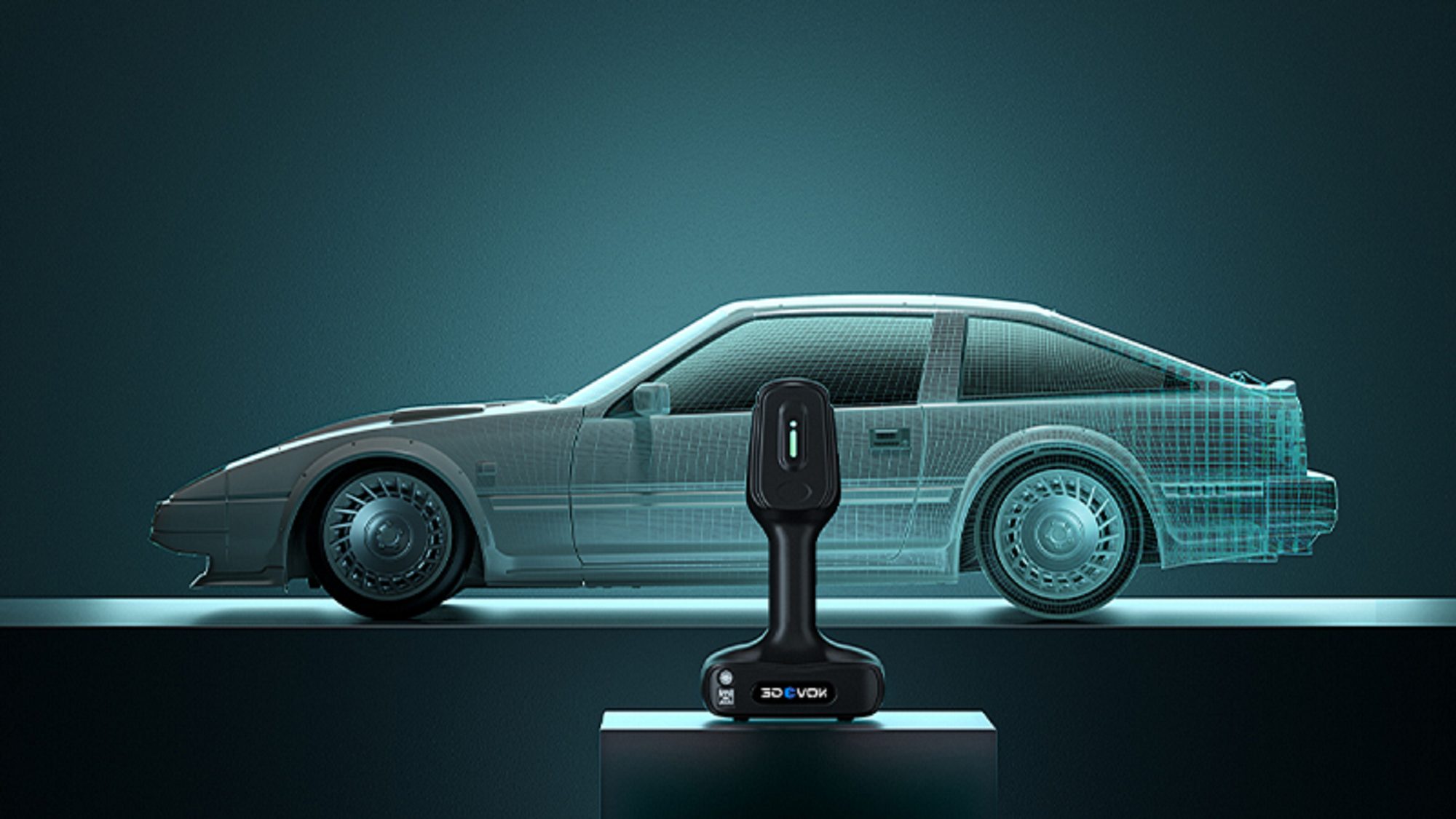

Innovation Of Reverse Engineering 3D Scan

- Innovation Catalyst: Reverse engineering through 3D scanning fuels innovation by transforming physical products into digital models, enabling rapid iteration and improvement.

- Enhanced Design Processes: Provides designers with accurate data, allowing for informed decision-making and fostering creativity in product development.

- Experiential Learning: Engages teams in hands-on experiences, bridging the gap between theoretical concepts and practical applications through tangible model manipulation.

- Streamlined Prototyping: Accelerates the prototyping phase by enabling quick alterations and refinements based on 3D scanned data.

- Cost-Efficiency: Reduces design and manufacturing costs by identifying potential flaws early in the process, minimizing waste and resource expenditure.