With the constant development of 3D scanning technology, the 3D digitization of archaeology is already inevitable. As a country with thousands of years of tracing history, China has seen a significant presence of 3D scanning in protecting cultural heritage.

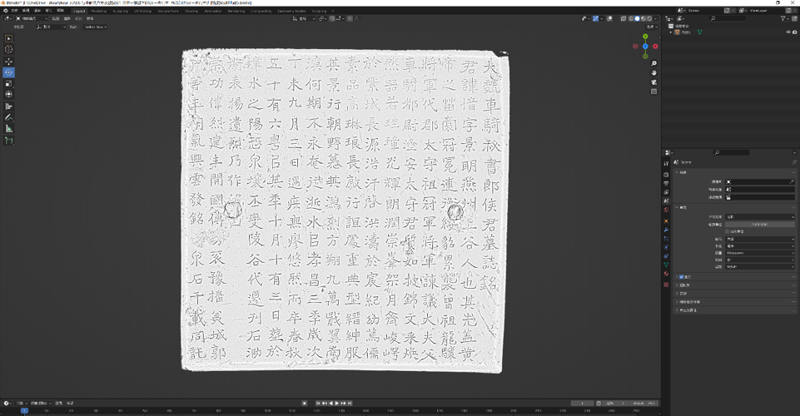

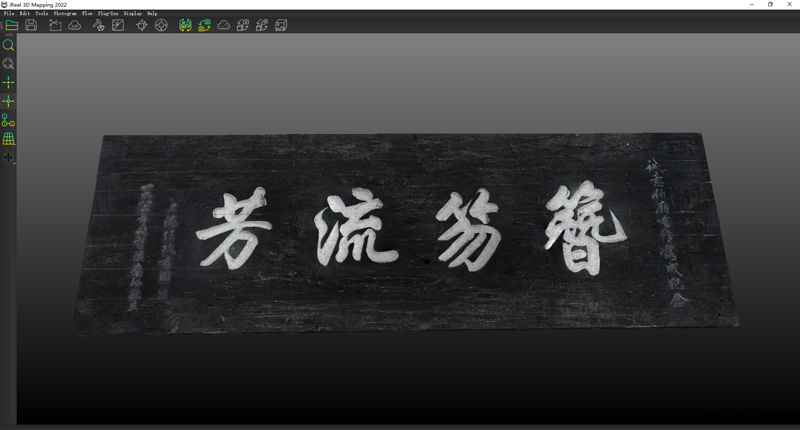

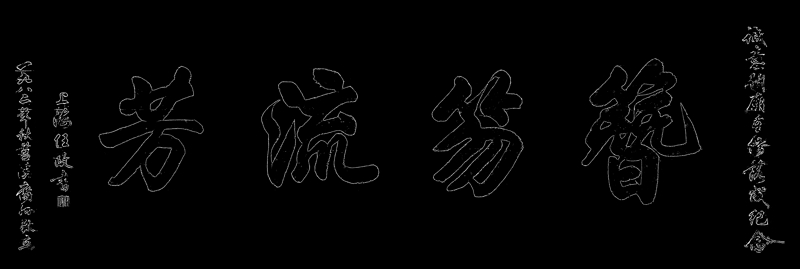

Today we mainly talk about a traditional craft of cultural heritage protection derived from China: rubbing, and how the help of 3D scanning replaces it.

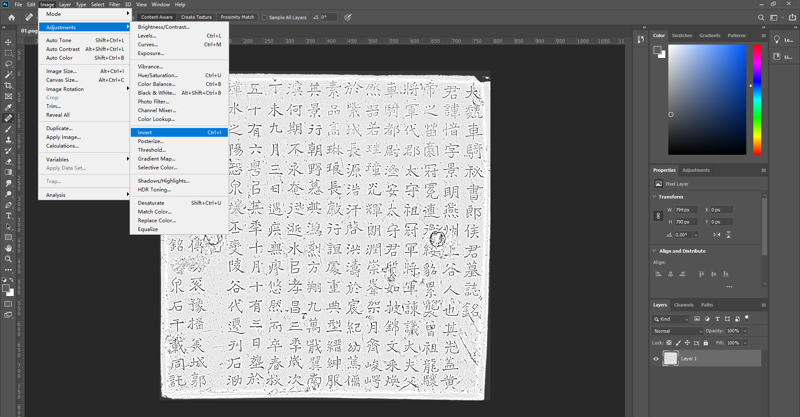

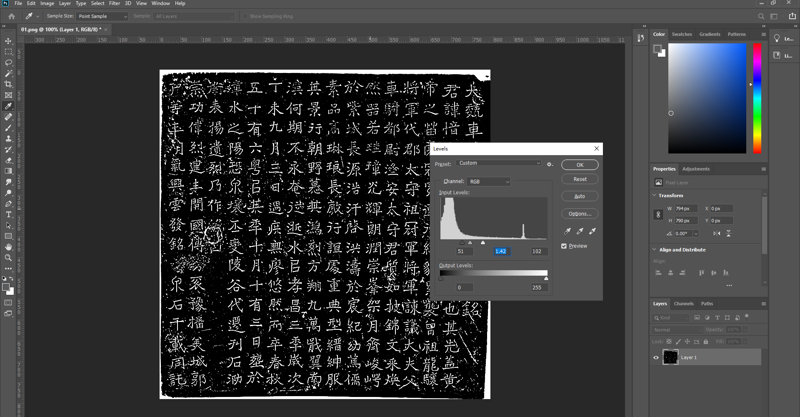

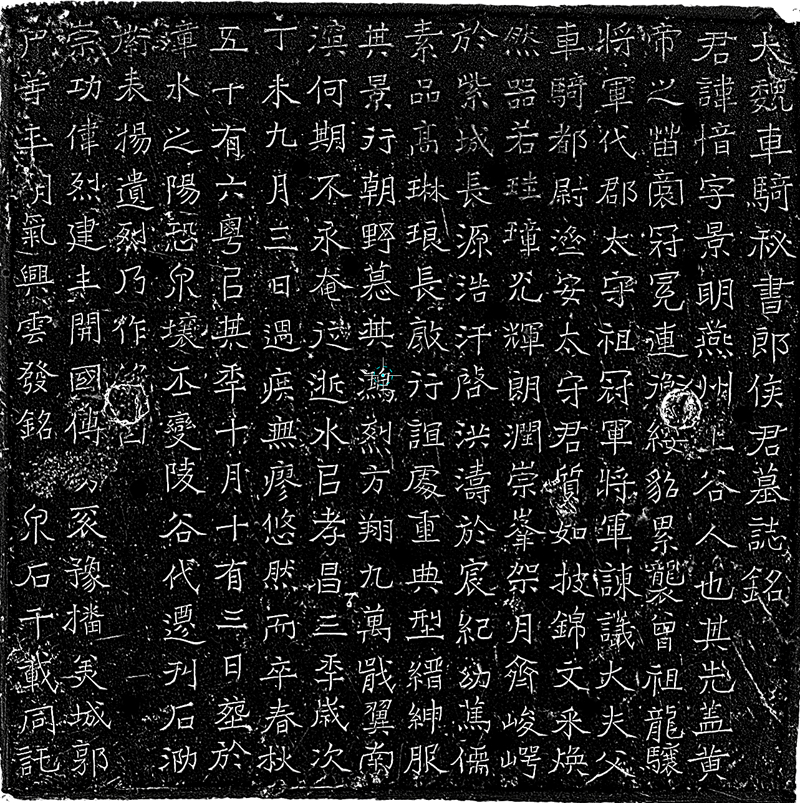

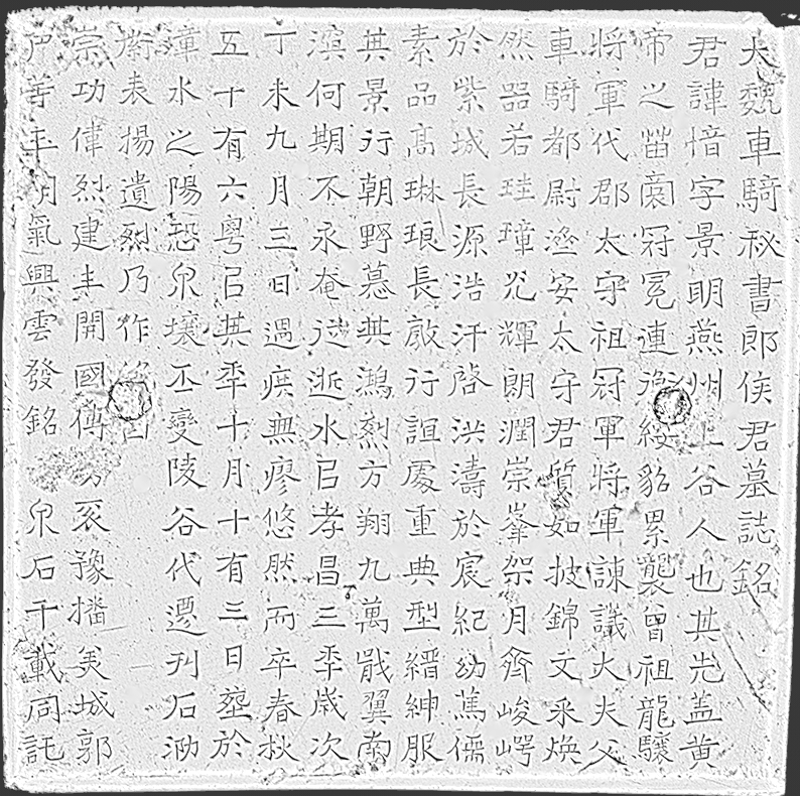

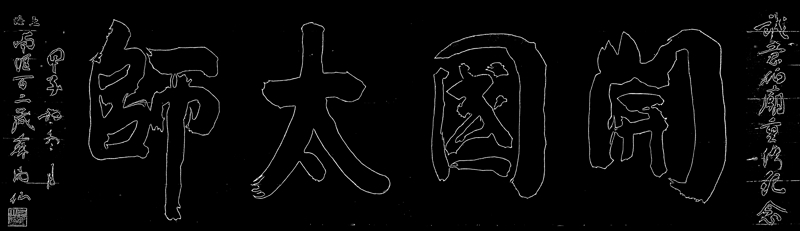

In archaeological practices, rubbing refers to a traditional method that aims to identify and analyze the shapes, characters, and patterns on the ancient plaque, tablet inscriptions, stone carvings, bronzes, etc.

The complete rubbing procedure uses Xuan paper and Chinese ink, for example, place a wet Xuan paper above an oracle bone script and slightly strike it with a brush to sink it in the groove. As soon as the paper starts to dry out, inking it evenly is when you finish a standard black-and-white rubbing.

Although the rubbing method is currently the mainstream transcription technique in the academic community, it still has a number of limitations. For instance, it is necessary to touch the oracle bones when making rubbings, which may cause damage to the bones.

In addition, the rubbing effect may be affected by temperature and humidity conditions as well as the operator’s own skill level. All the artificial factors are not conducive to neither the establishment of relatively mature rubbing standards nor long-term preservation and digital archives of cultural heritage.

SCANTECH (HANGZHOU) CO.,LTD’s 3D Scanning Solutions

SCANTECH (HANGZHOU) CO.,LTD’s 3D scanners provide non-contact and high-precision solutions for digital rubbings of cultural relics: from 3D laser scanners such as KSCAN-Magic, SIMSCAN, and TrackScan to infrared structured light 3D scanner iReal 2E.

The former choice provides up to 0.02 mm accuracy, and the latter one has the advantages of non-marker scanning, color restoration, and so on.

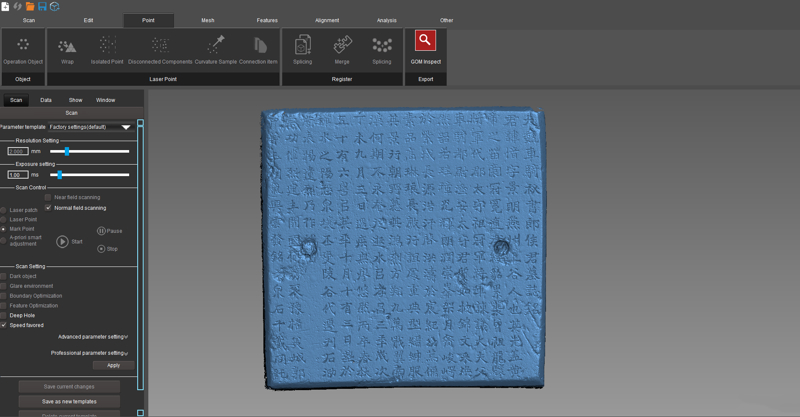

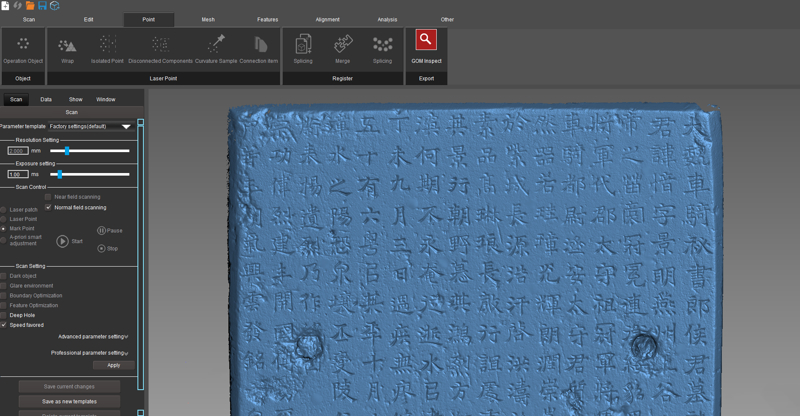

Digital Rubbing of Ancient Inscription (3D Laser Scanning)

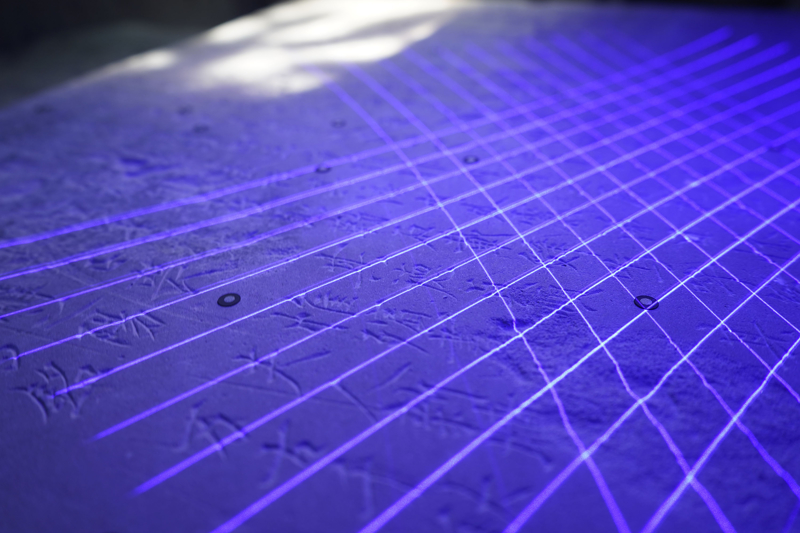

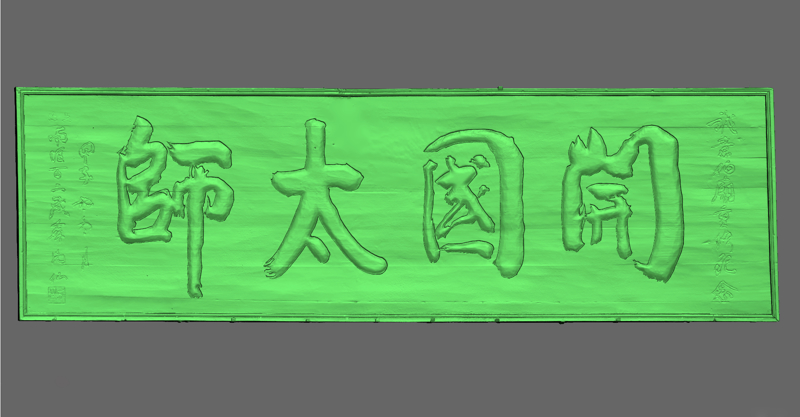

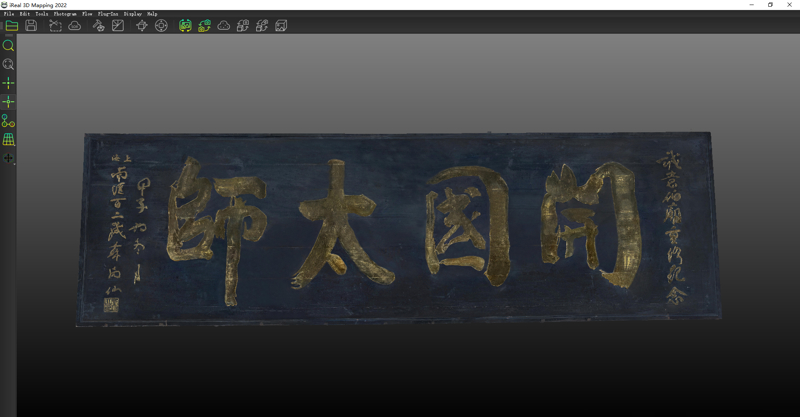

A case study regarding the 3D digitization of inscriptions was carried out by SCANTECH (HANGZHOU) CO.,LTD’s 3D laser scanner. After sticking some mark points on the inscriptions, the high-precision 3D data of the inscriptions were captured completely with its blue laser light.