Digital Orthopedic Solutions: 3DeVOK MQ 3D Scanning and 3D Printing for Customized Orthoses

08/19/25

With the increasing demand for personalized and precise orthopedic care, traditional manual measurements and orthosis fabrication methods struggle to meet efficiency and accuracy requirements. Addressing this challenge, the 3DeVOK MQ handheld 3D scanner, equipped with the 3DeVOK Airgo wireless handle and combined with TPM3D SLS (Selective Laser Sintering) 3D printing technology, provides medical institutions with a complete digital orthopedic solution for fully customized orthoses.

Background

In the process of orthotic treatment for the spine, wrist-hand, and ankle-foot, traditional m ethods face the following challenges:

– High-contact plaster molding: Patients need to maintain a fixed posture for extended periods, causing discomfort, and cleaning is difficult.

– Limited manual measurement accuracy: Data depends on the technician’s experience; errors may lead to ill-fitting orthoses or reduced corrective effectiveness.

– Long production cycle + low efficiency: From molding to final fabrication, the process is time-consuming, delaying rehabilitation.

– Lack of personalized design: Difficult to fully match the patient’s biomechanics, affecting fit and stability of the orthosis.

3D Digital Orthotic Solution

To address these challenges, 3DeVOK offers an integrated solution from 3D scanning to 3D printing orthoses. Key workflow steps include:

High-Precision 3D Scanning

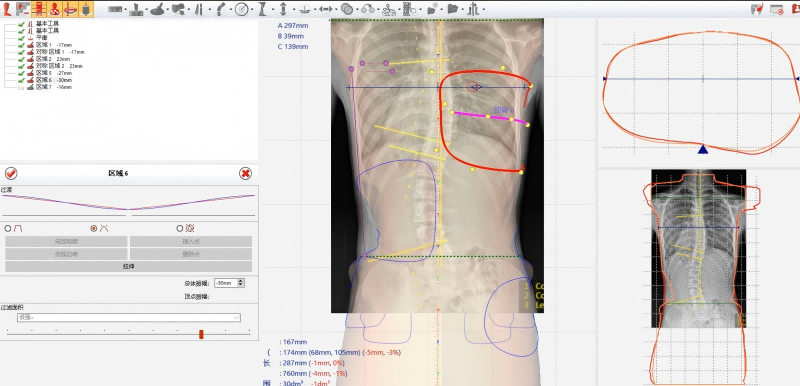

The 3DeVOK MQ professional 3D scanner captures high-precision 3D data of the patient’s spine, wrist-hand, and ankle-foot. Paired with the 3DeVOK Airgo wireless handle, it allows fully handheld, flexible scanning to capture every angle of the target area, ensuring precise replication of anatomical geometry. 3D scanning data is first processed in 3DeVOK Studio, including noise removal and mesh optimization, generating standard 3D files (e.g., STL, OBJ).

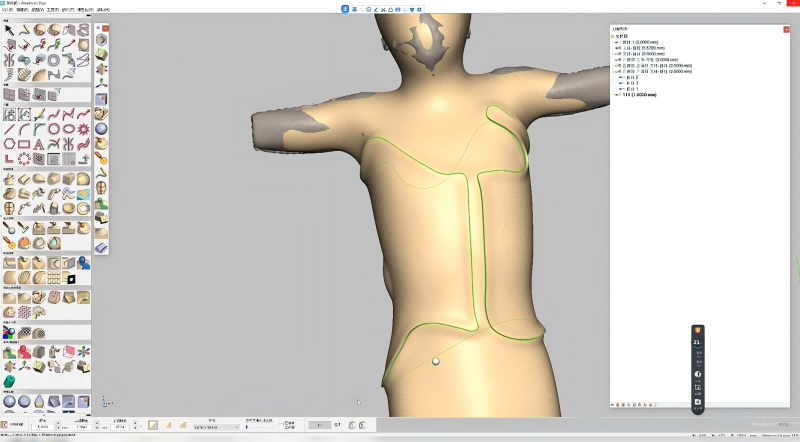

Digital Modeling and Personalized Design

Processed 3D files from 3DeVOK Studio 3D scanning software can be imported into modeling software such as Rodin 4D or Freeform for 3D design and structural optimization. Designers can perform local adjustments, geometry optimization, and integrate load analysis and ergonomic principles to improve orthosis stiffness, comfort, and fit.

High-Precision SLS 3D Printing

The finalized 3D model is printed using SLS technology by 3DeVOK partner TPM3D, directly producing the orthosis. SLS Technology allows complex structures with precise geometry, ensuring lightweight yet durable orthoses with improved comfort.

Closed-Loop Medical Application

The digital 3D orthoses can be integrated with rehabilitation and comprehensive therapy programs, providing a full-cycle, personalized recovery management system from orthotic design to patient rehabilitation.

Application Value

By implementing the 3DeVOK digital orthotic solution, medical institutions can achieve multiple benefits in the design and fabrication of orthoses:

– Improved orthotic accuracy: The 3DeVOK MQ 3D scanner captures precise patient anatomy, reducing errors from traditional manual measurements and ensuring orthoses fit individual body shapes more accurately.

– Shortened production cycle: With an extra-large scan area (1100 × 1000 mm), the MQ 3Dscanner can quickly complete full-body or localized scans. Its simple operation allows even beginners to use it easily, reducing training and operational costs.

– Enhanced patient experience: Light-free 3D scanning is safe for eyes, and combined with personalized design, it improves orthosis fit and wearing comfort.

– Easy replication and scalability: The digital workflow can be applied across departments and various types of orthoses, supporting standardized and large-scale adoption.

Case Support

Zhongshan Chen Xinghai Traditional Chinese and Western Medicine Hospital has applied this solution to spine, wrist-hand, and ankle-foot orthoses. Using 3DeVOK MQ for data acquisition and TPM3D 3D SLS printing for fabrication, multiple customized orthoses were successfully produced. Patient feedback indicates excellent fit, comfort, and significant rehabilitation outcomes. This case fully validates the feasibility and clinical value of the 3D digital orthotic solution.

Video Demonstrations: Spine scanning | Wrist-hand scanning | Ankel-foot scanning

Conclusion

The 3DeVOK MQ 3D scanner, as the core device of the 3DeVOK digital orthotic solution, paired with the 3DeVOK Airgo wireless handle and combined with SLS 3D printing technology, enables an efficient, precise, and personalized workflow for orthosis fabrication. This solution replaces traditional plaster molding with a non-contact, high-precision 3D scanning process.

Compared with the bulky, time-consuming, and often uncomfortable plaster molding method, the new 3D digital approach not only improves accuracy and efficiency but also significantly enhances patient experience. By integrating 3D scanning data with 3D printing, orthoses can be custom-designed to match the patient’s anatomy and rehabilitation needs. Hollow structures further provide breathability, lightweight comfort, and better wearability, offering medical institutions strong technical support to improve satisfaction and therapeutic outcomes in custom rehabilitation devices.

| Comparison | Traditional Plaster Molding | 3DeVOK MQ 3D Scanning + 3D Printing |

| Molding method | Contact method: directly apply the plaster to the patient’s body | Non-contact method: high-precision 3D scanning |

| Patient experience | Bulky, stuffy, long periods of immobilization, prone to discomfort | Fast, comfortable, openwork design for breathability and lightness |

| Accuracy | Depends on technician experience, with significant error | High accuracy (maximum accuracy up to 0.08 mm), data can be verified repeatedly |

| Production period | Complex processes and long production period | Combined with 3D printing to quickly complete production |

| Personalized design | Template-based design is difficult to tailor to individual needs | Customized design based on patient body type and rehabilitation needs |

| Brace performance | Heavy weight, poor breathability | Lightweight, breathable, comfortable to wear |

Want to learn more or get a customized solution? Contact us now!

Related Articles

View Our Product