3DeVOK MQ 3D Scanning + TPM3D 3D Printing: Making Scoliosis Correction No Longer “One-Size-Fits-All”

05/30/25

Scoliosis: The Overlooked “Invisible Killer”

Scoliosis is a common spinal deformity, particularly prevalent among adolescents. Traditional orthotic mold-making methods often rely on plaster casting and manual processing, which are time-consuming, labor-intensive, and struggle to achieve a precise fit. This impacts both the effectiveness of correction and the comfort of wearing the brace.

Zhongshan Chen Xinghai Hospital of Integrated Traditional Chinese and Western Medicine— the first tertiary Grade-A hospital jointly established by Guangdong and Hong Kong focusing on integrated Chinese and Western medicine — serves as a regional leader in bone disease rehabilitation. Its 3D Printing Medical Center is already providing patients with personalized, precision medical care.

Challenges: Traditional Methods Limit Orthotic Efficiency and Fit

- Time-consuming data collection: Plaster casting is lengthy and complex, with low patient cooperation—especially among children.

- Difficult to modify: Once a mold is altered, the original shape cannot be restored, making follow-up and fine adjustments challenging.

- Poor fit and comfort: Manual errors lead to mismatches between the mold and the patient’s actual body shape, reducing both corrective effectiveness and wearing comfort.

The Breakthrough: 3D Digital Workflow Reshapes Orthotic Care

The 3DeVOK MQ 3D color scanner and TPM3D P360 SLS 3D printing system together enable a fully digital workflow—from 3D scanning and design to final orthotic brace production—bringing speed, precision, and personalization to scoliosis treatment.

Non-contact 3D Scanning – Rapidly Capture Patient Body Data

The 3DeVOK MQ handheld 3D scanner, equipped with an infrared speckle light source, is certified by dual international standards—IEC 60825 (Laser Safety) & IEC 62471 (Optical Radiation Safety). It supports safe, non-contact scanning without light, providing a patient-friendly data acquisition process.

Using the 3DeVOK MQ non-contact 3D scanner, doctors can quickly complete a 360° body 3d scan of the patient’s torso in just one minute, avoiding the discomfort and pressure caused by contact, making it especially suitable for adolescent patients. The device supports wireless operation, eliminating cable restraints for more flexible and safer scanning, allowing doctors to freely adjust angles and positions in a clinical setting.

It also supports light-free scanning, significantly improving patient comfort and avoiding strong light stimulation. With a scanning accuracy of up to 0.08mm, it meets the fine modeling requirements for scoliosis correction molds. Featuring an ultra-large scanning area of 1,100mm×1,100mm, the system ensures smooth stitching, easy operation, and helps doctors efficiently collect patient body data.

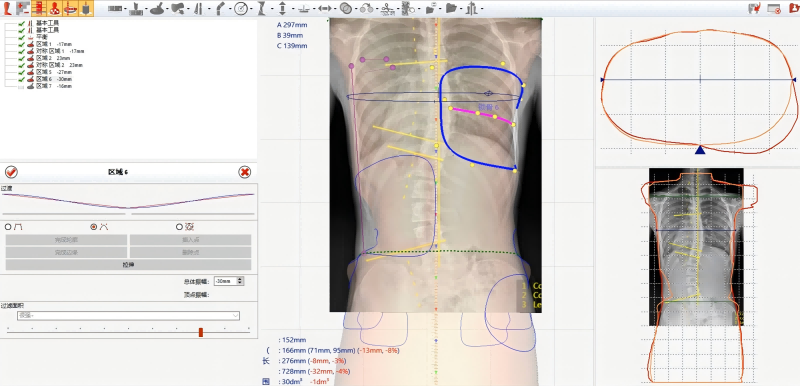

Digital Modeling and Design – Achieving Precise Orthotic Planning

Based on the body data obtained from the scan, technicians design a customized orthotic plan on the digital platform, optimizing the model structure based on spinal biomechanics. They then use X-ray images to adjust the corrective positioning, ensuring precise alignment of each vertebra and achieving a perfect combination of accurate fit and medical control.

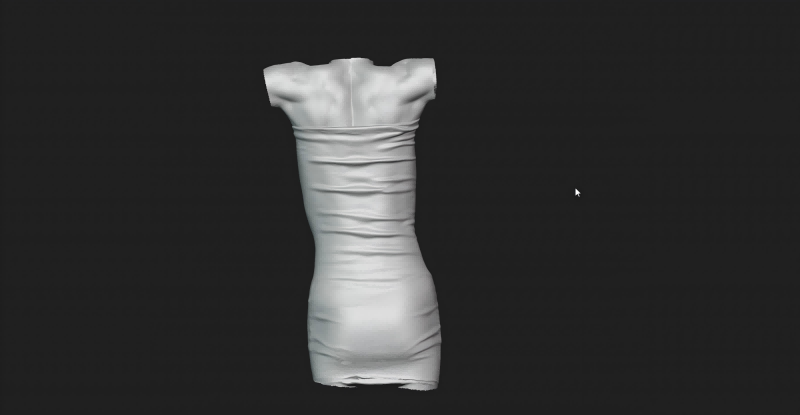

TPM3D SLS 3D Printing– Rapid Custom Mold Formation

After completing the orthotic model design, the hospital uses TPM3D SLS (Selective Laser Sintering) technology to 3D print the physical orthotic molds. The printing material used is TPM3D proprietary Precimid1190 medical-grade nylon powder, which offers high strength and some flexibility, making it especially suitable for creating orthotic supports that fit the body contours.

Compared to traditional printing methods, SLS technology offers advantages such as no need for support structures, high molding precision, and the ability to easily handle complex geometries. This allows the entire mold to be printed and formed in one piece, accurately reproducing the 3d scan model.

Fitting and Adjustment

After printing, the mold undergoes wear testing and necessary fine-tuning to ensure a perfect dynamic fit with the patient’s body, achieving the goal of “dynamic adaptation” in orthotic correction.

Results: Efficient Customization, Precise Fit, Enhanced Patient Experience

| Project | Traditional Method | Digital Method (3DeVOK + TPM3D) |

| Data Collection Time | 30-60 minutes | 1 minute |

| Model Modification | Non-reversible | Can be adjusted repeatedly |

| Production Time | 7-10 days | 2-3 days |

| Patient Feedback | Discomfort, high revision rate | High comfort, good compliance |

Through the digital workflow, the hospital has significantly shortened the production time, improved the fit rate, and enabled doctors to respond more quickly to patient needs, allowing patients to comfortably undergo long-term orthotic treatment.

A New Era in Digital Orthotics is Happening

With the increasing application of 3D scanning and 3d printing technology in medical rehabilitation, personalized treatment for scoliosis is gradually overcoming the limitations of traditional methods. The practices at Zhongshan Chen Xinghai Hospital demonstrate that the “precise, fast, and comfortable” scoliosis correction solution is becoming a reality, providing sustainable rehabilitation solutions for more patients.

If you would like to learn more about the complete application process of 3DeVOK + TPM3D SLS printing in scoliosis correction, or watch real-life case videos and demonstrations, visit our Youtube channel.

Related Articles

View Our Product