Unlike the photo modeling and 3D software modeling that have become very popular in the market over the years, for many customers, the experience of using 3DeVOK Mapping Software is still different from other 3D mapping software in the market: its multi-scene adaptability, easy operation, high efficiency, high quality and other experiences have greatly overturned the past 3D color texture mapping experience.

At present, the community version of 3DeVOK Mapping Software is open for the free trial, no activation code required, just download and use. All you need is a handheld laser 3D scanner + smartphone/DSLR camera to experience smooth, ultra-high definition 3D color mapping. In this article, for customers who are still on the fence about the software, we mainly popularize the difference between 3DeVOK Mapping Software and photo modeling, starting from seven scenarios: item adaptability, model accuracy, model surface quality, photo requirements, portability of mapping and retouching, and cost of entry. Considering that different customers have different needs and use different scenarios, the optimal solution for you is to make a purchase decision that maximizes benefits under budget-permitting conditions, taking into account your own situation.

Overview

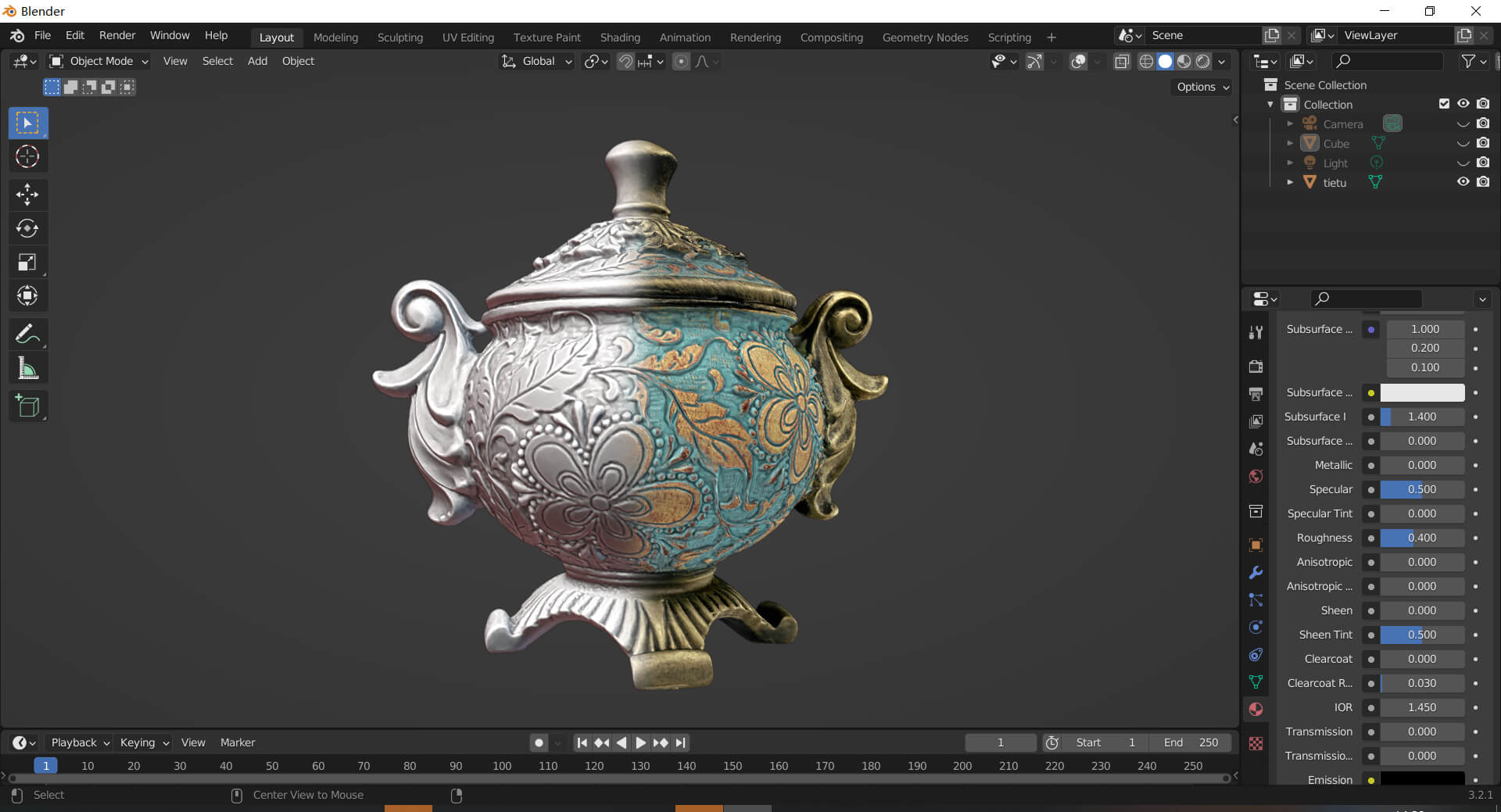

Laser 3D Scan + 3DeVOK Mapping Software

1. Main advantages:

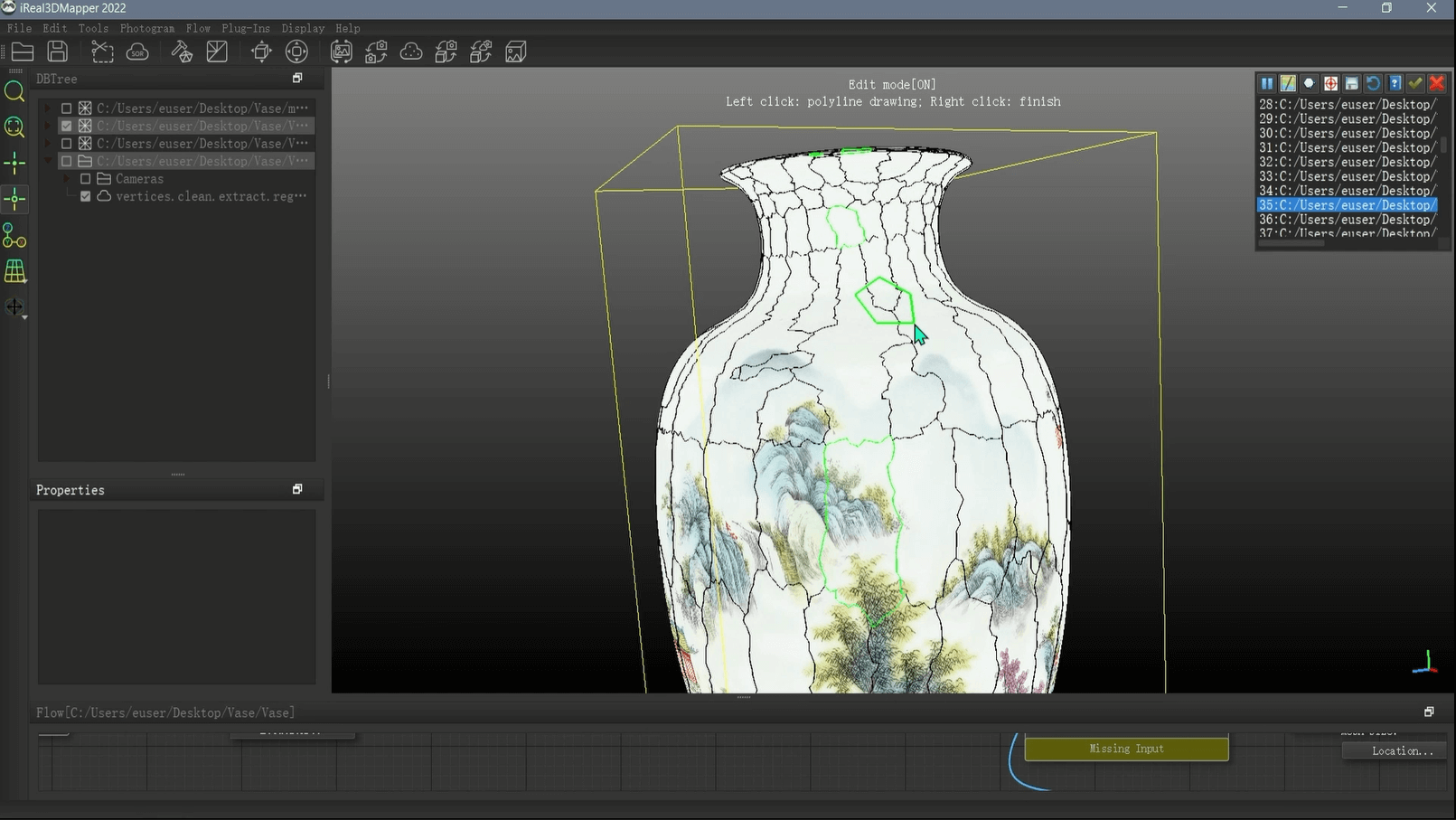

① Good adaptability of items: it can meet the needs of making color 3D models of most items.

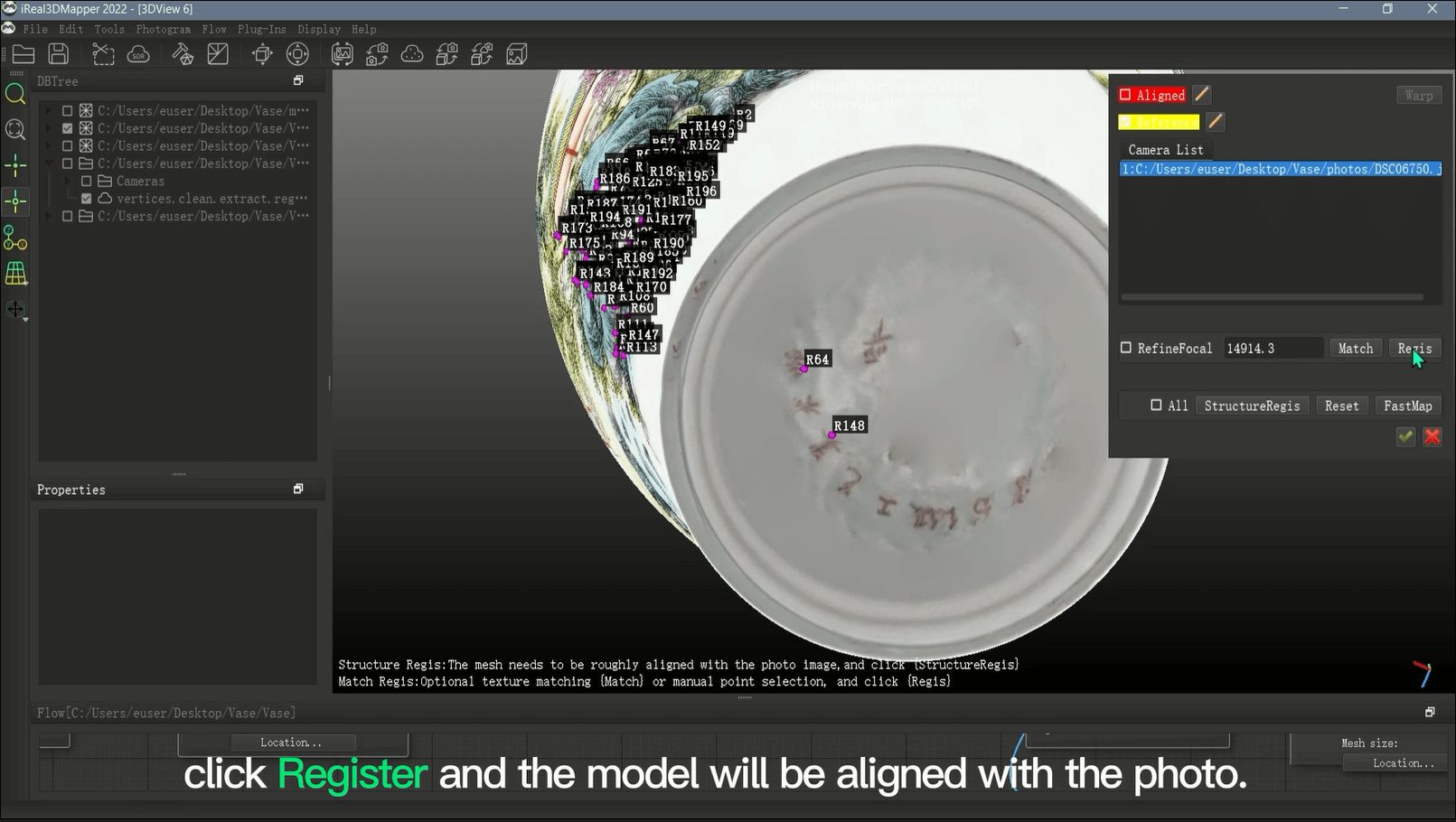

② Simple to use: easy to get started after self-learning; low requirements for technical personnel skills and experience; low labor costs (no need to be a senior engineer).

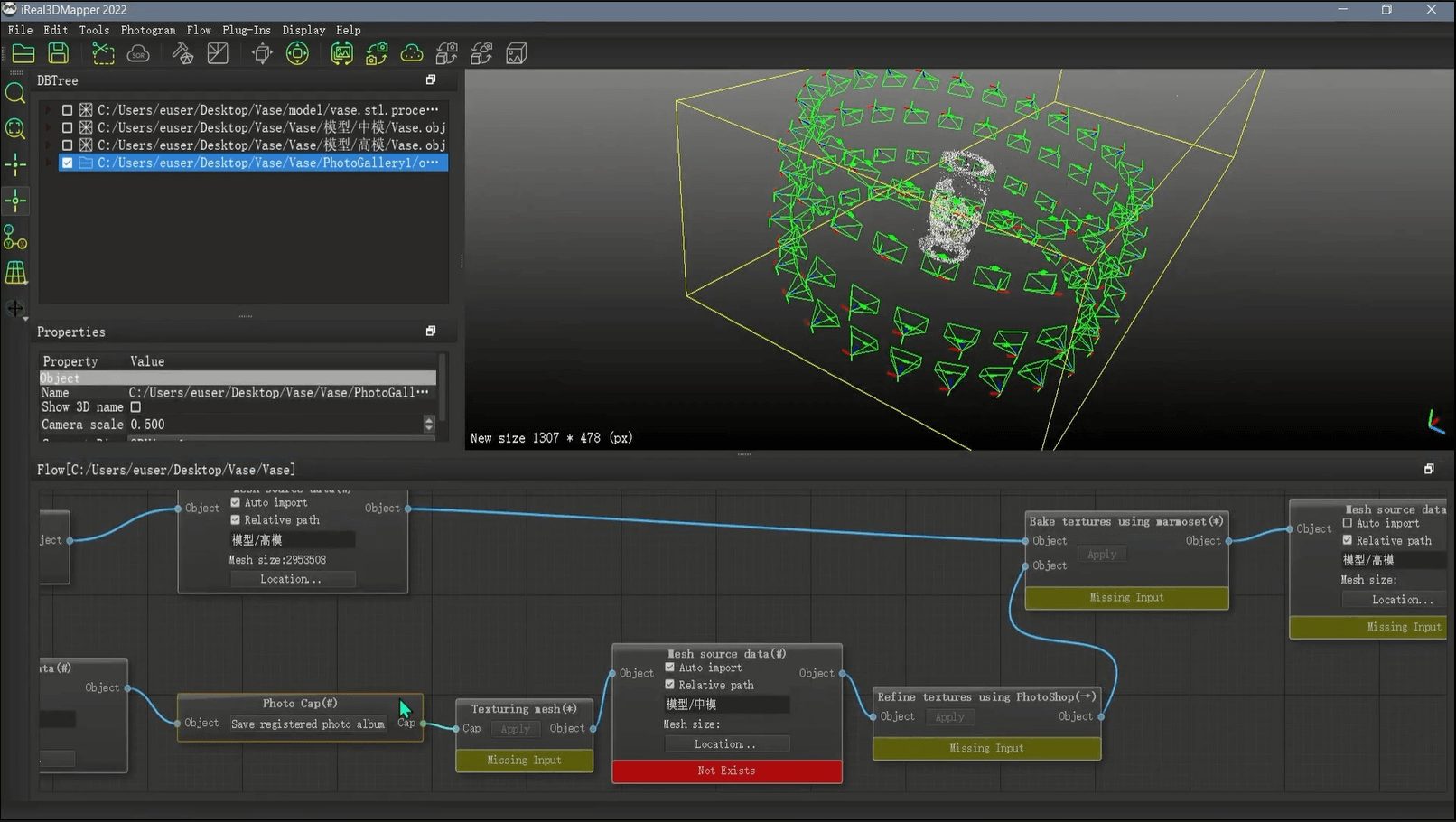

③ High-efficiency production: Most steps can be processed intelligently and automatically, and texture production and texture refinement can be completed within 30 minutes (regular model).

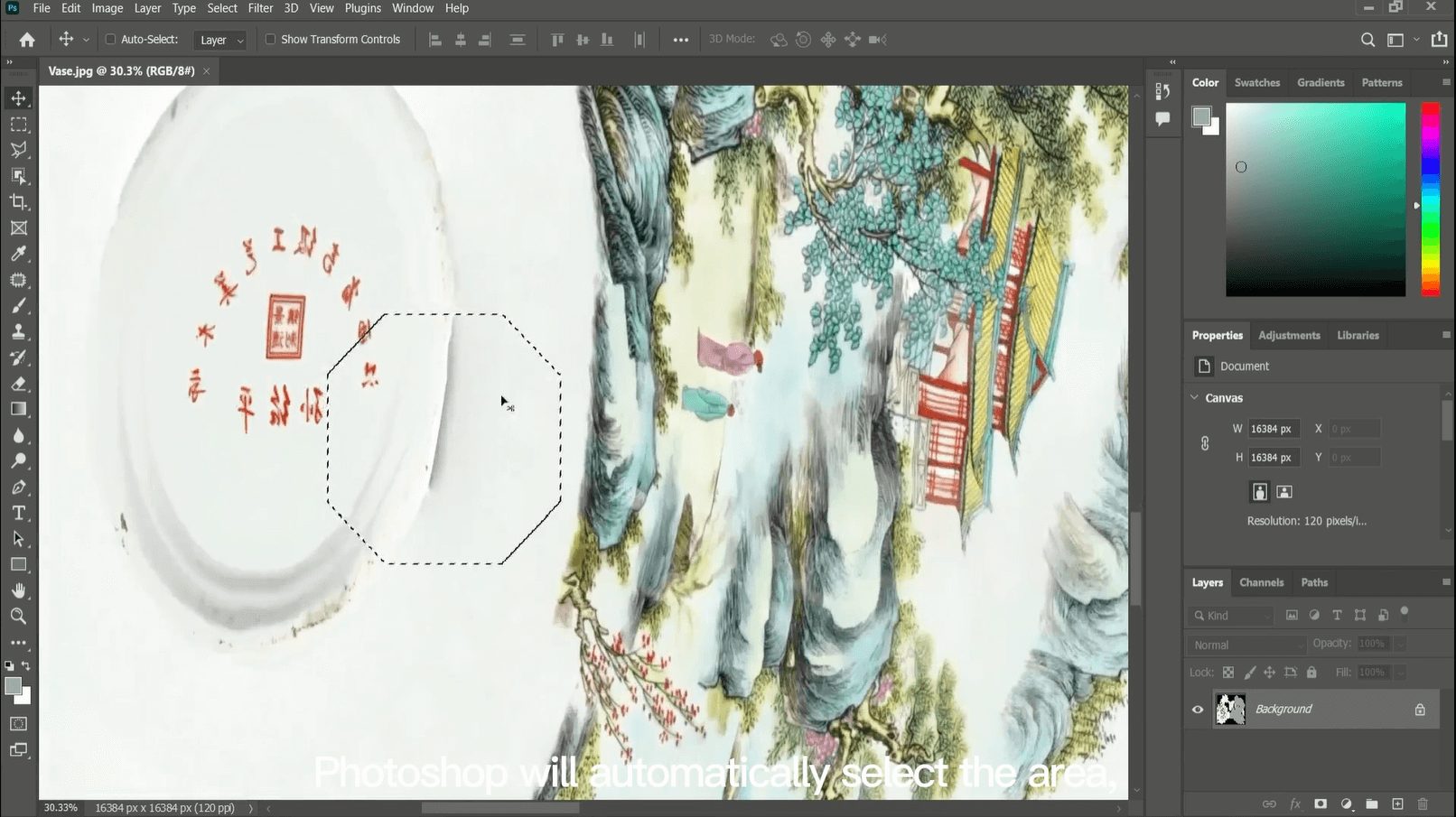

④ One-stop processing: When the local texture needs to be refined, there is no need to use multiple professional and complex third-party software. The engineer can use the seam line editing, single photo map replacement, one-click color leveling, Photoshop plug-in refinement and other intelligent functions in the 3DeVOK mapping software.

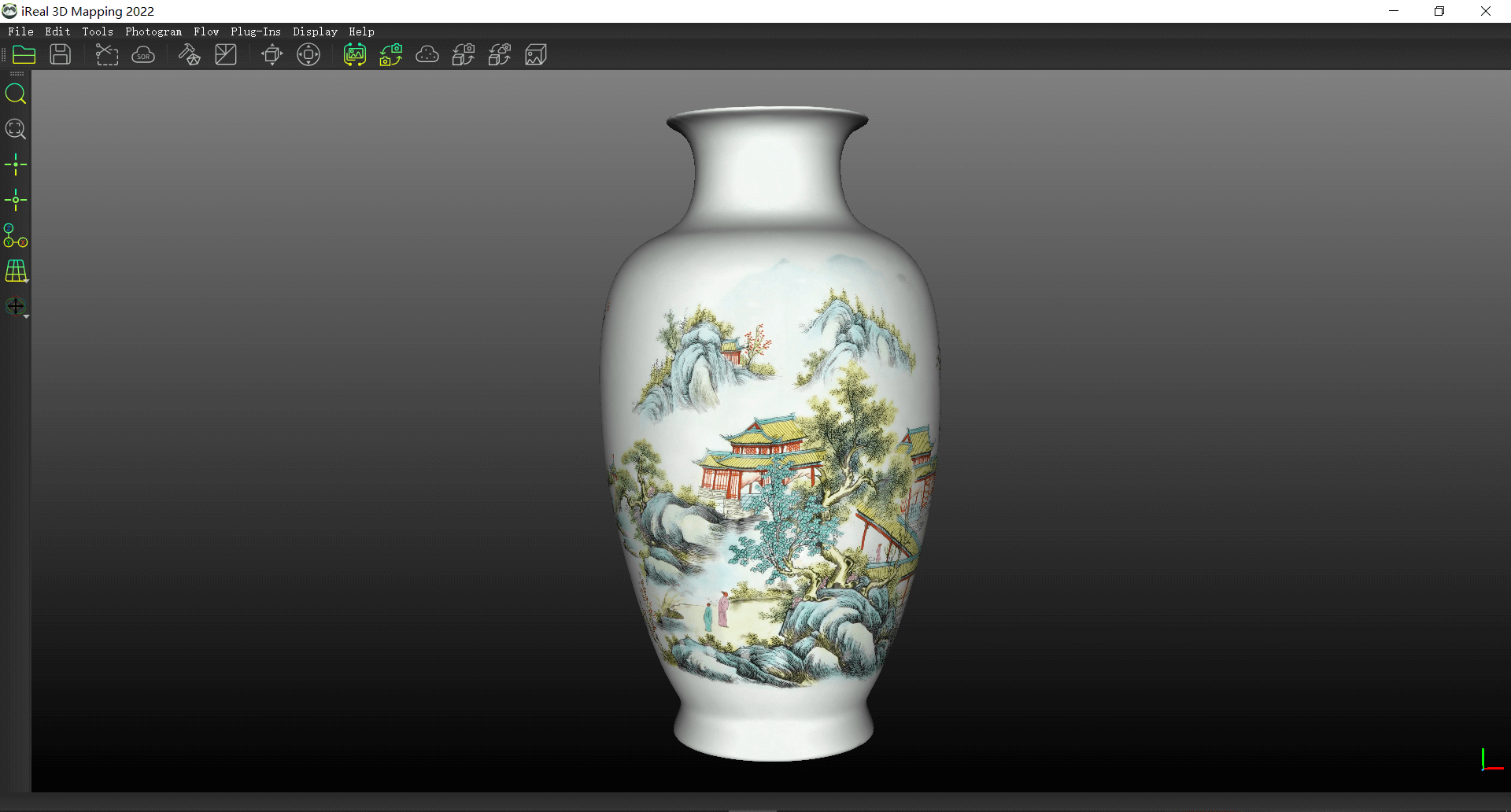

⑤ High-quality color textures: This solution can produce high-precision (in models and textures), high-accuracy and true-color 3D models, which are most suitable for customers with high requirements (such as industries of cultural relic protection, digital collections, etc.): 1:1 restoration of every real texture on the item is required.

2. Main disadvantages:

The cost of supporting software and hardware in the early stage is relatively high (however, the cost of post-production and supporting personnel is low, the production efficiency is high, and it can meet the requirements of color modeling for various items).

Photo Modeling

1. Main advantages:

① Complete photo modeling, low ancillary cost.

② For customers who do not have requirements for 3D model’s accuracy and texture accuracy, this method is more advantageous:

For matte items with rich and non-repeating textures and without complex structures (no hollows, deep holes, etc.), the advantages of this method are the most obvious.

2. Main disadvantages:

① Low adaptability of items: For items with few textures/high reflection, and thin-walled parts, etc., photo modeling may fail/issues may occur in local modeling.

②High requirements for operators: Operators need to have skills in SLR cameras, post-processing, local map refinement and other professional third-party software.

③High production cost: High-definition photo modeling requires more high-pixel photos, high-configured workstations, and longer computing time (the shortest takes 2-3 hours). When the local map needs to be refined, the operation is cumbersome and time-consuming.