3D Scanners Demystified: Aligning Technology with Industry-Specific Requirements

04/07/25

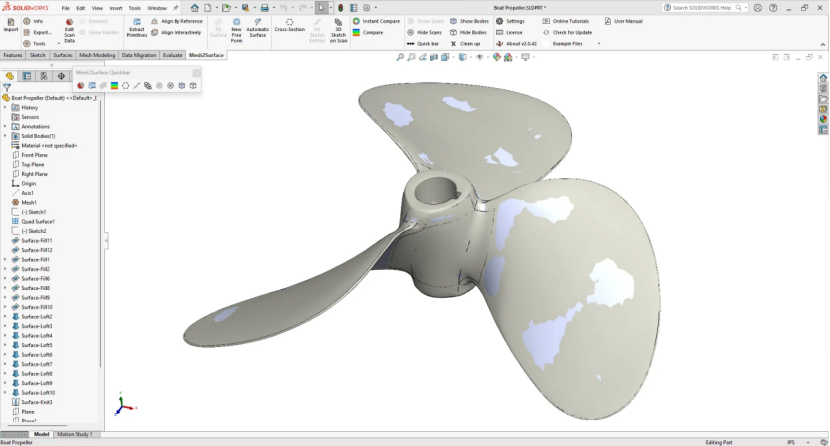

Using the right 3D scanner, paired with the best 3D reverse engineering software, is crucial for transforming scanned data into precise, actionable digital models. With the right tools and software, companies can accelerate product development, enhance design accuracy, and reduce time spent on revisions. In this article, we will explore some of the best practices for using 3D reverse engineering software, so we can maximize the potential of your 3D scans.

Selecting the Best 3D Reverse Engineering Software

Choosing the right 3D reverse engineering software is the first step to a successful project. Not all software solutions are created equal, and it’s important to consider factors such as the type of 3D scanner you are using, the complexity of the object being scanned, and your company’s specific needs. The software should be compatible with your scanning hardware and capable of handling the complexity of your scan data. At 3DeVOK, we help businesses identify the software that is best suited to their reverse engineering needs, ensuring that the software and hardware work in harmony for optimal results.

Integrating Software with 3D Scanning Tools

One of the most important aspects of reverse engineering is ensuring seamless integration between your 3D scanning hardware and software. This allows for more accurate data capture and easier conversion into digital models. Whether you are using laser scanning or structured light scanning technology, the right reverse engineering software should support your scanning tools, improving overall accuracy and efficiency. Integration reduces the need for manual adjustments and ensures that the digital model closely resembles the physical object.

Optimizing Scan Data for Product Development

Once the scan data is captured, optimizing it for product development is essential. Reverse engineering software allows businesses to edit and refine scanned data, smoothing out rough surfaces and converting point clouds into solid models. This optimization process is crucial for ensuring that the final product design meets your specifications and is ready for manufacturing. In many cases, reverse engineering software can also help with designing complex geometries that would be challenging to create manually. Our team works with businesses to ensure that every scanned model is optimized for efficient and effective product development, ensuring faster iterations and greater accuracy.

Leveraging 3D Reverse Engineering Software for Prototyping

Another key benefit of using the best 3D reverse engineering software is the ability to quickly create prototypes. By using the refined digital models, businesses can create physical prototypes faster and more cost-effectively. This ability to quickly iterate on designs helps reduce time-to-market and ensures that the final product aligns with initial concept designs. Additionally, it enables companies to test designs in the real world, evaluate functionality, and make adjustments before committing to full-scale production. This process improves product quality and reduces the risk of costly errors.

Continuous Improvement and Collaboration

Finally, the process of reverse engineering should be seen as a continuous improvement cycle. As new tools and software versions become available, it’s essential to keep refining your process to ensure that your models and designs remain cutting-edge. Collaboration with other departments and stakeholders in your company can further improve the accuracy and effectiveness of the reverse engineering process. Regular feedback and iteration can significantly enhance the final product.

Conclusion

3D reverse engineering software plays an important role in transforming raw 3D scan data into accurate, usable models. By selecting the right software, ensuring integration with your scanning tools, optimizing the data for prototyping, and continuously refining the process, businesses can streamline their product development process and improve accuracy. At 3DeVOK, we are dedicated to helping you select and implement the best 3D reverse engineering software to meet your project needs, ensuring a smoother and more efficient product development journey. With the right tools and practices in place, businesses can achieve faster, more accurate, and cost-effective product designs that meet market demands.

Related Articles

View Our Product