Aesthetics Of 3D Scan Reverse Engineering

- Aesthetics: Enhances the visual appeal of products by allowing for detailed analysis and modification of existing designs.

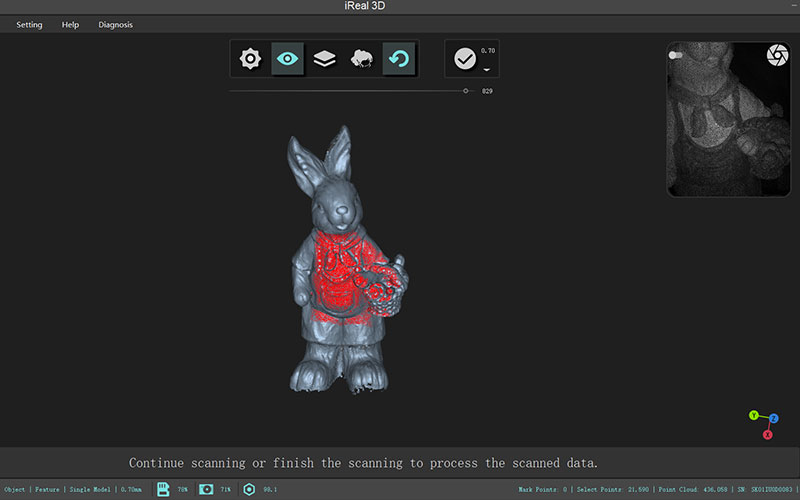

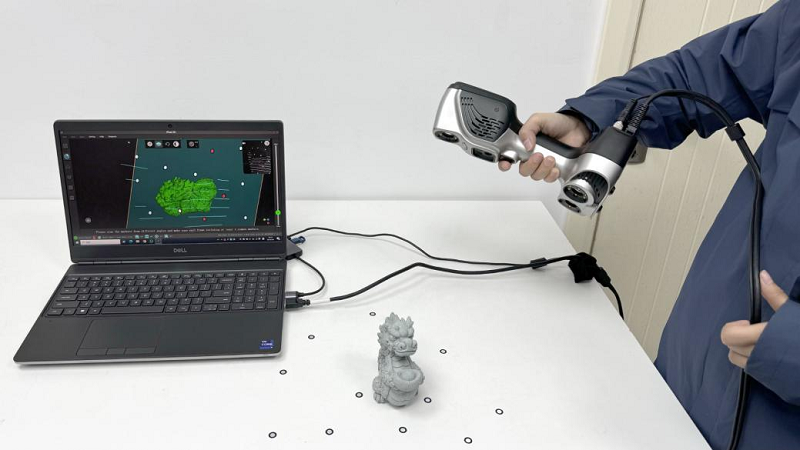

- Precision: Utilizes high-resolution 3D scans to capture intricate details and textures, ensuring accuracy in reproducing forms.

- Customization: Facilitates unique design alterations, enabling personalized aesthetics that cater to specific consumer tastes.

- Efficiency: Speeds up the design process by quickly generating accurate models from existing objects, saving time and resources.

- Innovation: Encourages creative exploration by allowing designers to reimagine and refine existing designs through iterative prototyping.