Precision Of 3D Laser Scanning For Reverse Engineering

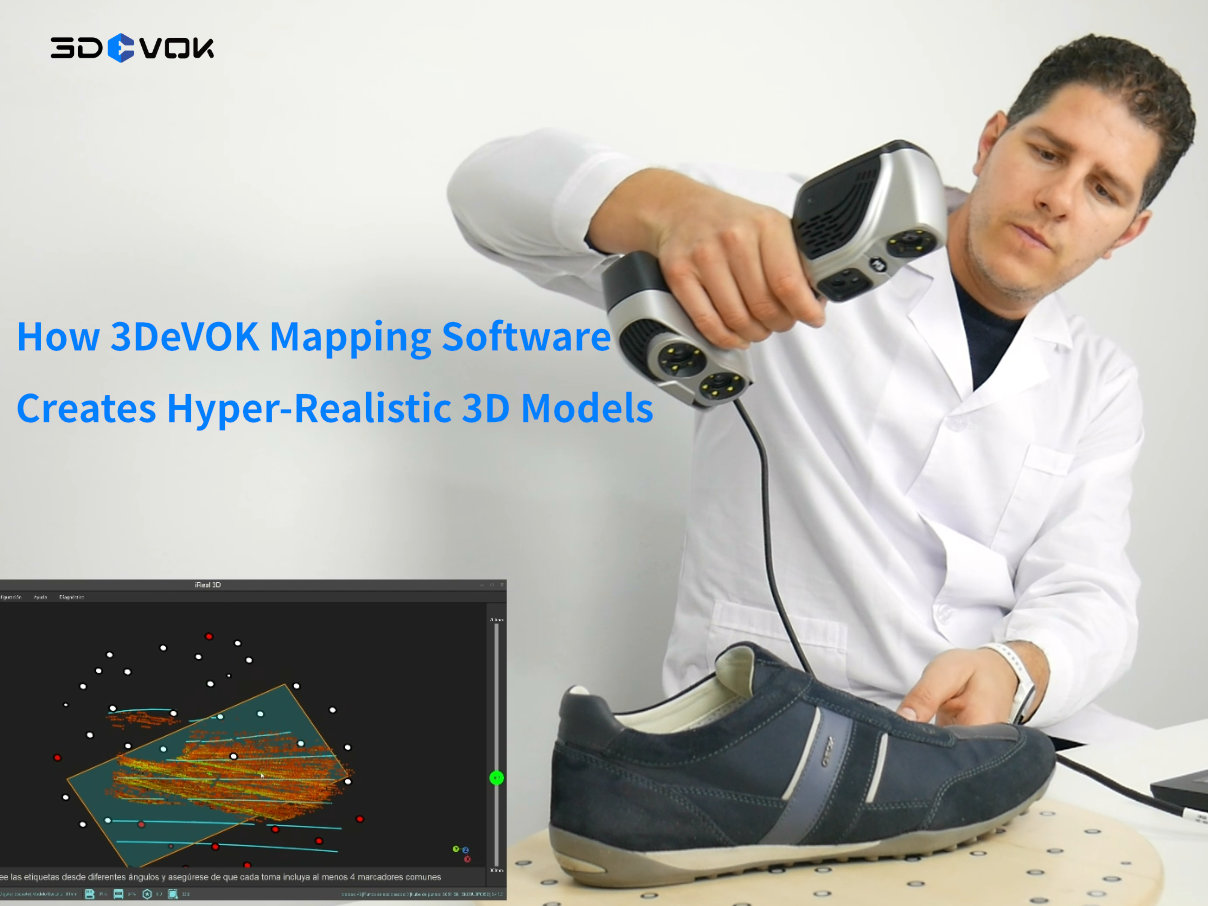

- High Precision: 3D laser scanning captures intricate details with remarkable accuracy, ensuring that every curve and feature of an object is recorded.

- Rapid Data Acquisition: The technology enables quick scanning of complex shapes, significantly reducing the time required for data collection compared to traditional methods.

- Enhanced Reverse Engineering: Scanned data can be easily converted into CAD models, facilitating design innovation and product development.

- Versatile Applications: Suitable for various industries, including manufacturing, aerospace, and automotive, allowing for broad reverse engineering opportunities.

- Improved Prototyping: Streamlines the prototyping process by providing precise measurements, which lead to better-fitting components and faster iterations.